-

- Free Word Search

Tens of millions of tons of food are wasted annually in Japan. The government has enacted the Food Loss Reduction Promotion Law, which requires consumers, food manufacturers and retailers, food service providers, and others to take initiatives to reduce food loss.

Traceability, quality control, and process control are indispensable information control systems for food processing.

Company A, which manufactures and sells food products, had been using a UPS (Uninterruptible Power Supplies) to back up the control equipment in its facilities for these information management purposes, in preparation for emergencies. However, even with the UPS in place, there were still cases of food waste (food loss) due to missing data and control failures. Mr. K, a manufacturing technology manager, explains: "In the food processing process, we had to control the temperature and time.

In the food processing process, if any part of the data such as temperature, time, or flow rate is missing, the quality of the product is affected and the product must be disposed of. However, the control equipment would pause and restart for some reason, causing data to be lost, resulting in the disposal of food. (Mr. K)

Although a power failure was the most likely cause, Mr. K hit a wall.

We thought that the power outage would not affect us because we had a UPS installed. So we assumed it was due to noise and took various measures, but nothing seemed to improve the situation, so we were troubled." (Mr. K)

When Mr. K consulted with a distributor about the problem, he was introduced to SANYO DENKI. After hearing about the problem, the SANYO DENKI representative hypothesized that the problem was caused by the use of a "constant-on commercial type" UPS.

[Hypothesis put forward by SANYO DENKI]

(1) Power supply factor

When the power motor starts up at the factory, the voltage drops temporarily and the UPS switches to battery operation.

When switching to battery operation, a momentary breakdown (5msec) occurs.

(2) Equipment Factors

The capacitors in the DC power supply deteriorate over time, causing the electrolyte to volatilize and the ability to store electricity to deteriorate.

The DC power supply in the equipment also experiences voltage drops, causing the control equipment to restart.

The lead-acid batteries deteriorate under high temperatures, so they may not be able to provide the backup time specified in the catalog. It was also pointed out that lead-acid batteries deteriorate under high temperatures, so they sometimes do not provide the backup time specified in the catalog. (Mr. K)

Following these findings, Company A carried out measurements within the factory with the support of SANYO DENKI, and the results confirmed these hypotheses.

"Firstly, there were frequent voltage drops of around 10%. This was the limiting voltage drop at which the UPS would switch to battery power supply. It would not have been surprising if it had switched to battery operation mode at any time. We also found a UPS that was still issuing a battery alarm even though it had only been replaced two years ago. Due to the size of the UPS, it had been installed in a position where the operation panel was not visible, which apparently led to the alarm being overlooked." (Mr. K)

A SANYO DENKI representative suggested using the lithium-ion battery model of Uninterruptible Power Supplies, SANUPS E11A-Li, in power supply quality priority mode (constant Inverter operation).

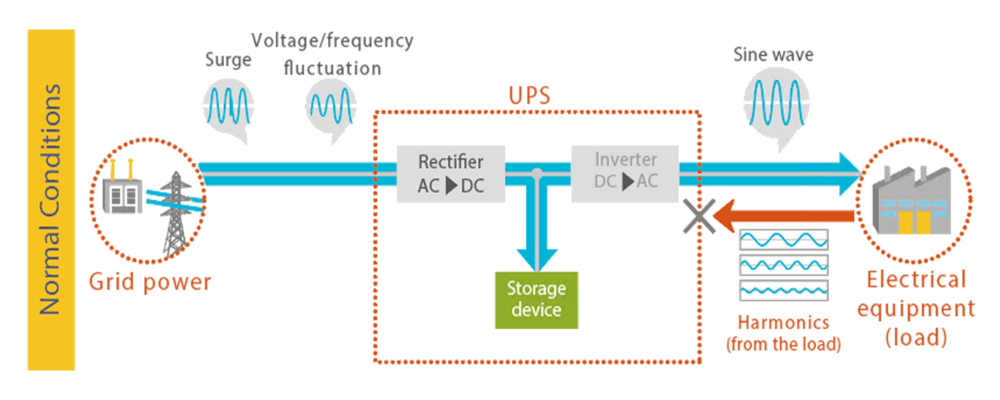

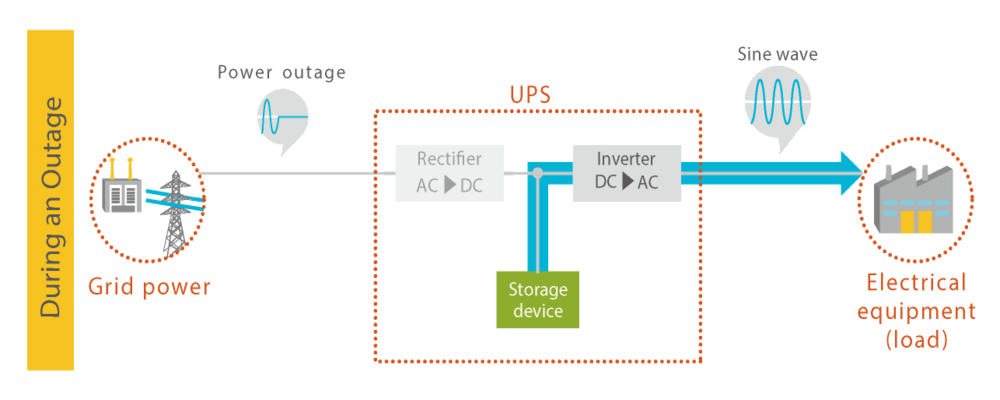

What is power supply quality priority mode?

This is a method of supplying electricity to electrical equipment at all times through an inverter. Even during a Inverter outage, power is supplied via Inverter, so there is no need to switch power supplies, and power can be supplied without interruption without voltage fluctuations. Because power is always supplied via Inverter, this is a highly reliable power supply method.

Based on the results of the measurements, Company A decided to adopt Uninterruptible Power Supplies" SANUPS E11A-Li" and replaced the UPS in the factory. Mr. K explains the effects of the introduction as follows:

"It is more compact than our current UPS, so we were able to store it neatly inside the switchboard. Also, the storage battery has been changed to a lithium-ion battery, which eliminates the need for regular inspections and replacement like with lead batteries, reducing the hassle and costs. It also comes with a longer-than-usual three-year warranty *1, which gives us peace of mind. Above all, the greatest achievement was that we were able to identify the cause of the data loss and resolve the problem. Process problems not only result in food waste, but also in the preparations and adjustments required for restarting operations, which take a lot of time. The improvements have improved our work efficiency and reduced overtime, so we are very grateful to SANYO DENKI. We will be sure to consult you again if we need anything."

1 For more information on the 3-year warranty for UPS, please click here.

*For more information on lithium-ion batteries, compare the battery life of UPSs (Uninterruptible Power Supplies)! Also see

Published on: