-

- Free Word Search

The expansion of the online shopping market has led to an increase in demand for logistics warehouses. This trend has accelerated since the COVID-19 pandemic led to increased demand for staying at home, and there is a demand for even greater improvements in work efficiency through smarter logistics, including labor saving and automation.

Company E provides logistics warehouses to a variety of businesses across the country. The company had installed multiple UPS systems in its warehouses as a protection against power outages and voltage drops for the management PCs that monitor their transport equipment.

Mr. D, the head of the System Management Department at Company E, explains the background to the UPS introduction as follows:

"Sometimes packages stop during transport for some reason, but because there is no function to notify the user of this error, it takes a considerable amount of time to identify where they have stopped. For this reason, the customer asked us to monitor where on the line packages were stopped. We developed a device to monitor the location of packages and installed it on each line in the warehouse. A management PC was installed on each line in conjunction with the transport device, but there were quite a few PCs in one warehouse. We installed a UPS as a countermeasure against power outages and voltage drops." (D)

However, this UPS ended up causing Mr. D more anxiety.

"There were several times when we suddenly realized that the UPS had broken down, and this became a new source of worry for us," said Mr. D.

The number of UPS in the warehouse has increased to a considerable number, and due to concerns about malfunctions, it has become necessary to manage these UPS.

"We wanted a system that would enable us to remotely monitor multiple UPS systems, respond quickly when a breakdown or malfunction occurs, and schedule battery replacements," said D.

In addition, the batteries had to be replaced frequently due to deterioration, which raised concerns about maintenance.

"Maintenance requires a lot of manpower. Also, maintenance work can sometimes disrupt business, so we wanted to keep the frequency of replacement as low as possible," said Mr. D.

Mr. D, who was troubled by UPS malfunctions and maintenance, consulted SANYO DENKI had a proven track record in previous projects.

After listening to Mr. D's concerns, SANYO DENKI representative proposed the hybrid power supply system "SANUPS E11B." This proposal piqued Mr. D's interest.

"The first thing that caught our eye was the three-year warranty, which addressed our concerns about breakdowns. We also learned that, in response to the customer's request to "monitor multiple UPS units in the warehouse all at once," we could install a LAN Interface Card, which would allow us to constantly monitor the status of all the UPS units at once. Furthermore, there are features such as an automatic battery check *2 and an alarm that notifies us when the battery is nearing the end of its life, so we felt that we could meet the customer's needs." (Mr. D)

*2 Cycle can be selected from 30 days, 90 days, or 180 days.

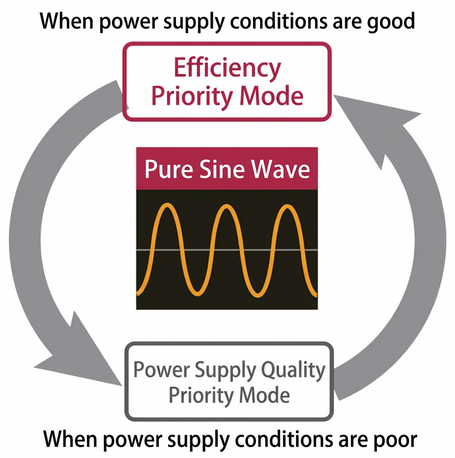

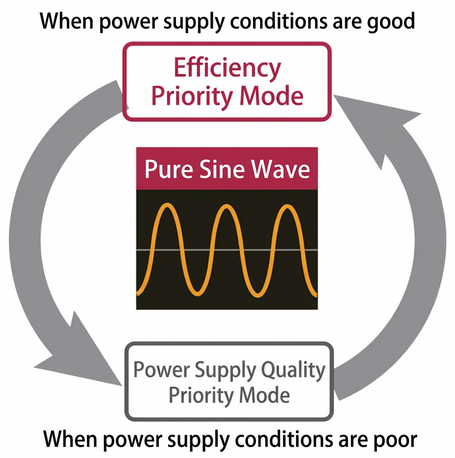

This is a method in which the UPS automatically selects the optimal power supply mode. With high power supply quality and little power loss, it is ideal for machine tool control units and elevators.

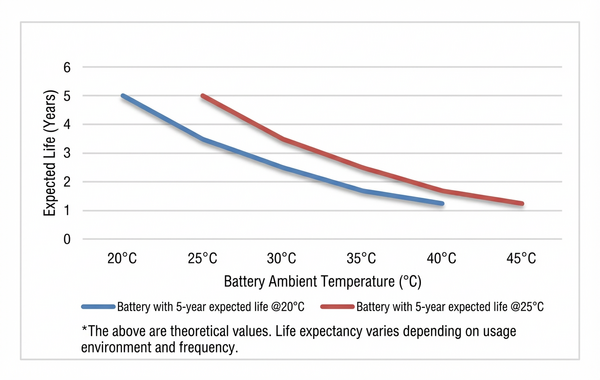

▲ Correlation between battery ambient temperature and expected lifespan (reference)

Regarding the issue of "battery life" of conventional products, the "SANUPS E11B" not only enables control that does not put a strain on the battery, but also has an expected lifespan that is approximately one year longer than conventional products *3, which was very attractive and was expected to reduce maintenance labor.

"The wide input voltage range *4 reduces the frequency of switching to battery operation, even when the input power supply is unstable, and prevents battery wear and deterioration. A longer battery life also reduces the amount of maintenance work required, so this point was also very appealing to us."

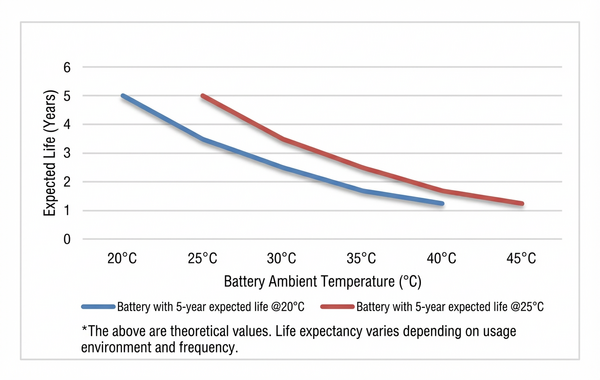

▲ Correlation between battery ambient temperature and expected lifespan (reference)

*3 Battery life expectancy: 5 years @ 20℃ → 5 years @ 25℃ (approximately 1 year longer life)

*4 The input voltage range is 55 to 150 V for the 100 V type and 110 to 300 V for the 200 V type. The input frequency range is 40 to 120 Hz.

These proposals greatly satisfied Mr. D and his team. E conducted a six-month field test (pre-implementation test) to formally adopt SANUPS E11B.

"We've been using SANYO DENKI 's UPS for six months now, and we've confirmed that it's as reliable as we expected. We feel safe replacing all our UPS with SANYO DENKI products." (Mr. D)

Shortly thereafter, Company E officially adopted the SANUPS E11B and replaced all of its UPS, which numbered approximately 100 units.

"Even now, a year and a half after the installation, we have not had any UPS failures. We are very satisfied with both the quality and performance. Setting up LAN Interface Card requires some technical knowledge and is something we are unable to do in-house, so when we consulted SANYO DENKI, they immediately provided technical support. We are grateful for their prompt response. We expect there will be major changes in the logistics system in the future, so we would like to continue consulting SANYO DENKI on various matters." (Mr. D)

release date: