-

- Free Word Search

Company M, which manufactures and sells food processing machines such as food dryers, was working on developing a new model of food dryer with improved drying capacity in response to requests from clients. Mr. Y from the development department said the following.

"Food dehydrators dry food by circulating heated air. The performance of a dehydrator is determined by the amount of airflow and humidity, but commercially available fans cannot produce the required amount of airflow. Also, there are no fans that can withstand the temperature inside a dehydrator, so we attach blades to a three-phase motor to circulate the hot air."

We were considering continuing to use a three-phase motor to rotate the blades in the new model as well.

"In order to improve the drying capacity of the new model, we needed to increase the rotation speed of the blades and increase the airflow. However, we couldn't increase the rotation speed any further with the current motor. We considered increasing the motor's capacity, but this would mean increasing the motor size and making the dryer larger. To improve the drying capacity without changing the size of the equipment as much as possible, we needed to select a small, high-torque motor." (Mr. Y)

Mr. Y visited the SANYO DENKI booth at the exhibition and asked if there was a better solution. A SANYO DENKI representative visited him later to hear more about the problem and suggested replacing it with a servo motor.

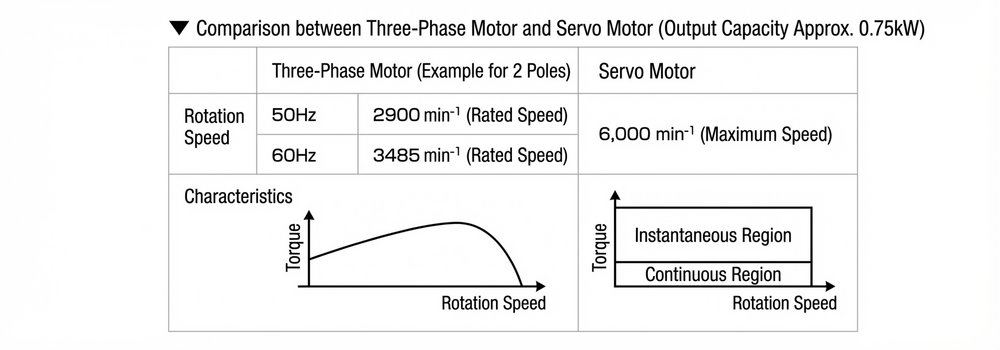

"They proposed replacing the three-phase motor with a servo motor. A three-phase motor has the characteristic of slowing down its rotation speed as the load increases, but a servo motor does not have the slippage that a three-phase motor has, and can maintain high rotation speed regardless of the load. A servo motor with the same output capacity can handle a wider range of loads than a three-phase motor, so we were able to expect to improve the blade rotation speed without changing the motor size. Using a servo motor would also enable us to increase the airflow of this dryer." (Mr. Y)

Company M immediately created a prototype using a SANYO DENKI servo motor and confirmed that the air volume was significantly higher than the current model.

Looking back on this development, Mr. Y had this to say:

"I'm glad I consulted with SANYO DENKI this time. They explained everything to me carefully, and the servo motor became a new option for me. They also customized the shaft processing, which helped us reduce in-house man-hours." (Mr. Y)

Company M says it plans to continue developing its products while consulting with SANYO DENKI whenever any issues arise.

release date: