-

- Free Word Search

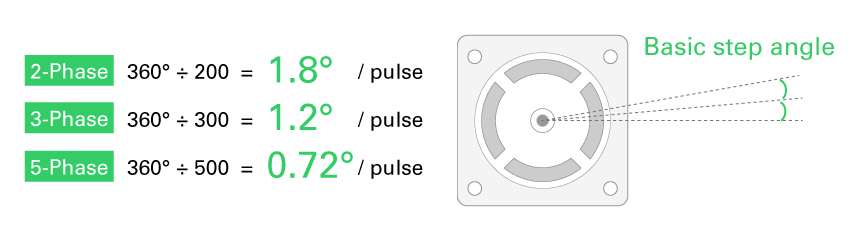

A stepping motor is a type of control motor that can be positioned without a sensor. It is also called a pulse motor, step, or stepper motor.

Although there are disadvantages, such as the risk of stepping out, compared to servo motors with sensors, they can achieve positioning "inexpensively and with simple control." For this reason, they are often installed in "equipment that needs to achieve relatively simple positioning without incurring a lot of cost."

A stepping motor rotates at a fixed angle (step) like the second hand of a clock. Positioning is achieved by switching (controlling) this angle.

Taking advantage of the advantage of "low-cost and simple positioning control," stepping motors quietly enrich our lives in a variety of situations.

Related article: Knowledge "What is a stepping motor? Explanation of its mechanism, types, usage (drive system and control method), advantages and features"

We provide a more detailed explanation of the mechanism and features of stepping motors.

Although we do not see stepping motors directly in our daily lives, they are at work inside many machines that support our daily lives in a variety of situations.

Where are they actually used? We will introduce some representative examples.

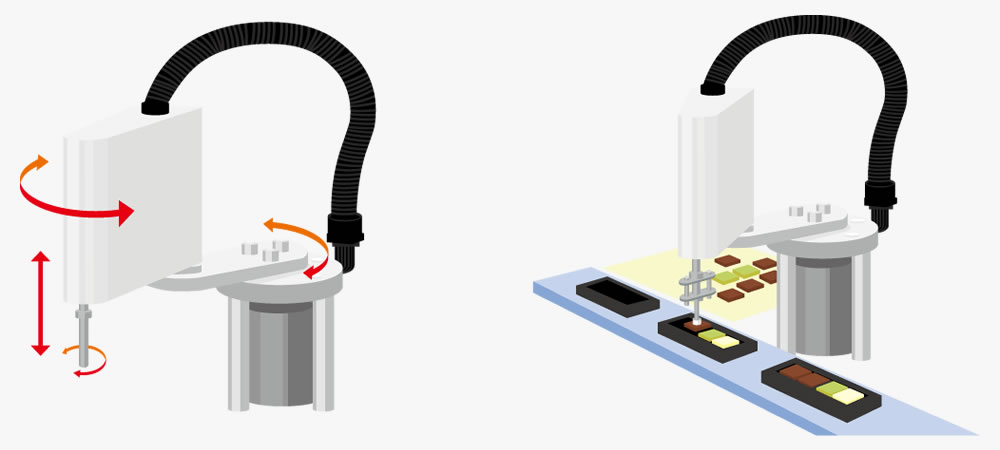

Due to labor shortages, mechanization and automation are becoming more and more important every year. Stepping motors are used in "factory robots" that solve these problems.

A typical example is the "Scara robot (horizontal articulated robot)." Scara robots, which mainly move horizontally, excel at relatively simple tasks such as "transportation, assembly, and screw tightening." For example, it is easy to imagine a scene where chocolates are packed into special boxes.

Stepping motors, which do not have sensors, also have the advantage of being good at "relatively simple repetitive movements." They can also achieve positioning at low cost, making them ideal for SCARA robots, which mainly perform horizontal movements.

On the other hand, for robots that require more complex movements (vertical, curvilinear), servo motors with sensors are used.

In this way, stepping motors and other motors are making significant contributions to manufacturing in terms of labor savings, quality improvement, and cost reduction.

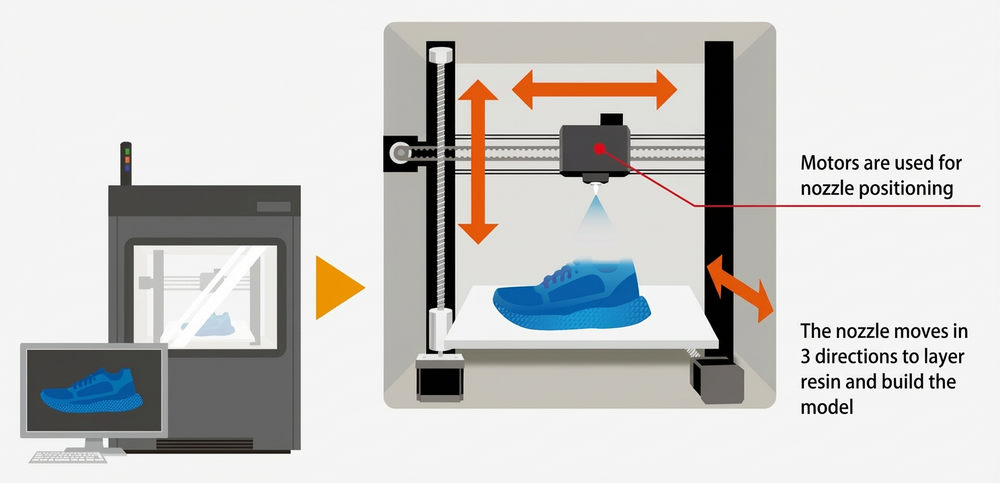

A 3D printer is a device that creates three-dimensional objects by spraying and layering resin. It can create any design you can think of, which has brought about major innovations in the manufacturing and construction industries, such as generating better ideas and reducing development times and costs. Many people were probably surprised to hear that the construction period for the Sagrada Família was shortened by more than 150 years by introducing IT technologies, including 3D printers.

So, in what parts of a 3D printer are stepper motors used?

The answer is in the drive unit of the nozzle that sprays the resin. As shown in the diagram below, a stepping motor is used to position the nozzle.

By using a three-axis (XYZ) motor, the nozzle can be "moved in three dimensions" to accumulate resin and create a 3D object.

Precise positioning using controlled motors is essential to create complex 3D objects.

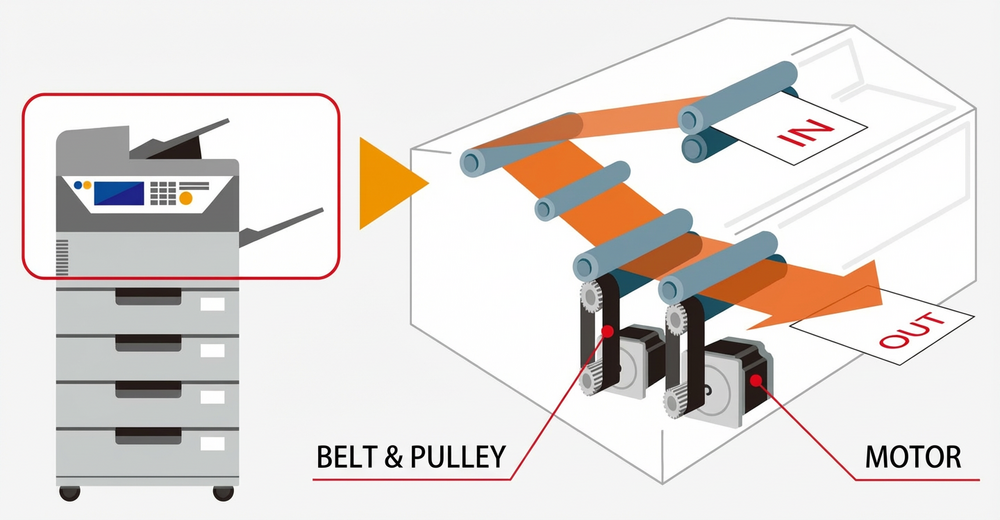

Nowadays, in Japan alone, nearly 500,000 copiers and multifunction machines are shipped annually. Although paperless systems are being encouraged, they are essential office automation equipment for efficient business operations. Recently, the number of multifunction copiers that can print data from smartphones and so on has increased even at convenience stores, and many people find them convenient.

So, the very simple task of "reading information and outputting it on paper" is a simple one, but where in that process are stepping motors used?

This is probably what you might imagine. The stepping motor exerts its power in the "document scanning" and "paper feeding" operations.

First, the operation of scanning the original. Control and positioning are performed to read the original smoothly and without distortion. Next, the operation of feeding the paper. Multiple "paper feeding rollers" are used inside the copy machine. The role of the stepping motor is to move these rollers and feed the paper "quickly and accurately."

Stepping motors play an important role in producing beautiful, distortion-free copies without printing errors.

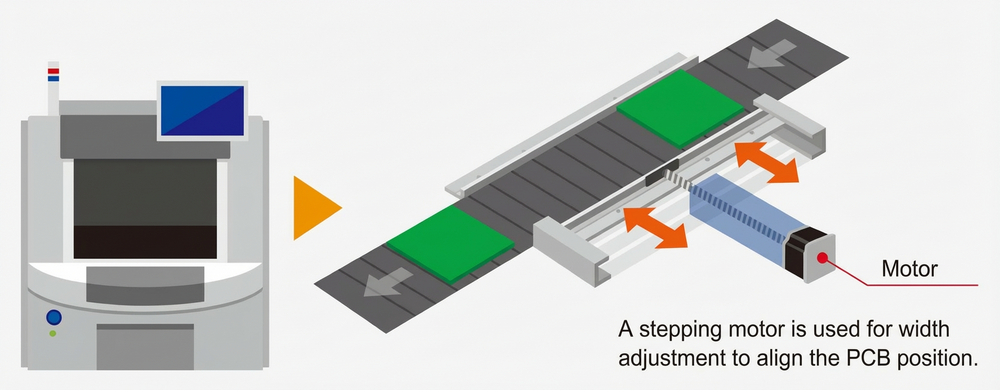

First, let us explain what kind of machine a PCB inspection device is. PCB inspection device is, as the name suggests, a device that "inspects" "circuit boards." "Electronic circuit boards" are used in all the electrical appliances and automobiles around us. Electronic circuit boards contain many electronic components that work together to ensure that products function properly.

If there is even the slightest defect in the board (for example, a short in one part of the solder joint), the product will not be able to function. In order to avoid such defects, a "board inspection device" is used during inspection.

Circuit board inspection involves multiple processes such as "printing process inspection," "mounting process inspection," and "reflow process inspection," and traditionally these were performed by human eyes. However, due to the miniaturization of circuit boards and labor shortages, the role of inspection using "circuit board inspection equipment" is becoming more important.

In what part of this PCB inspection equipment does the stepping motor work? It is in the "alignment that aligns the PCB." This may be a little difficult to understand, so we will explain it using the diagram below. The PCB is placed on a belt, inspected at each stage, and then sent to the next stage. If the PCB is "misaligned or bent at an angle" during this process, accurate inspection is not possible. The stepping motor controls the alignment position so that the PCB can be sent for inspection in a "perfectly aligned" state.

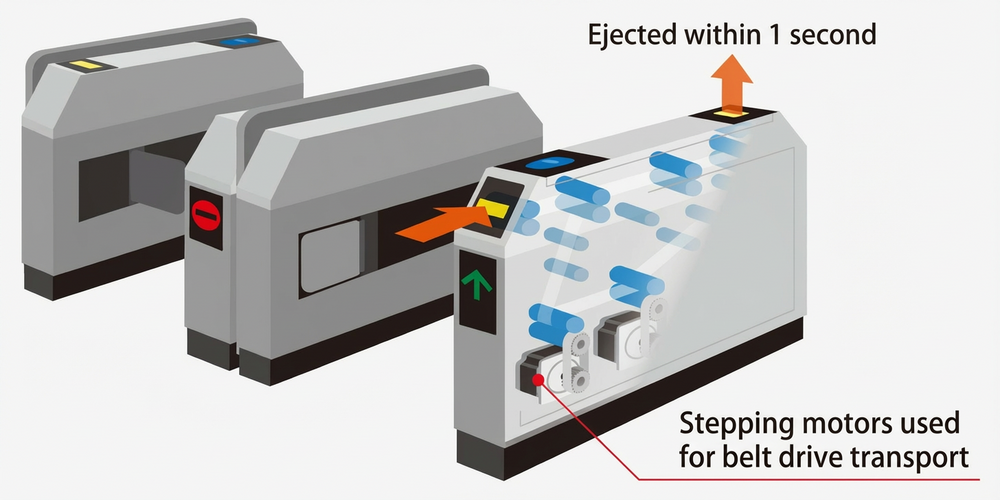

Stepping motors are also used in the automatic ticket gates that we use to pass tickets at train stations.

The device is used in the "transport section" that carries the ticket from the insertion slot to the exit. Inside the automatic ticket gate, a transport belt transports the ticket, and this belt is powered by a stepping motor. During rush hour such as in the morning, the ticket needs to be transported from entrance to exit "within one second" to avoid causing congestion. In addition, by stopping precisely at the exit, the ticket can be delivered exactly to the hand.

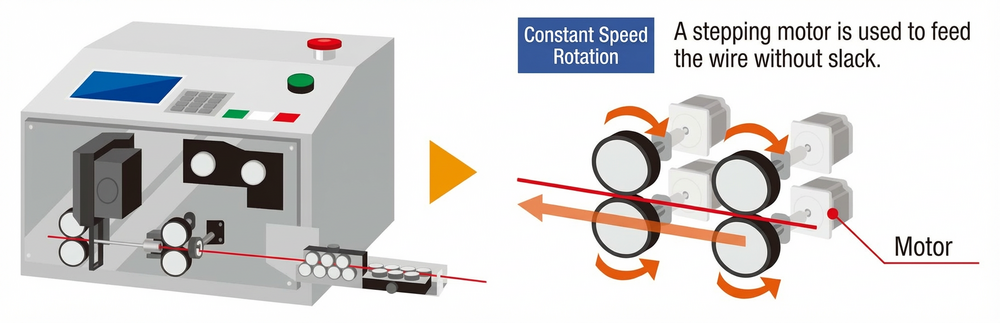

A wire processing machine is a machine used to process wire rod.

Wire is a long, thin piece of steel that looks like a wire. Wire processing machines process wire in various ways, such as cutting it to length, turning the coating on the tip, twisting it into wire, and making screws and springs.

Stepping motors are used in the "wire feed section" of wire processing machines. As shown in the diagram below, they feed the required length of wire to the processing section. The reason stepping motors are so useful is that by taking advantage of their feature of "rotating at a constant speed," the wire can be fed to the processing section without loosening.

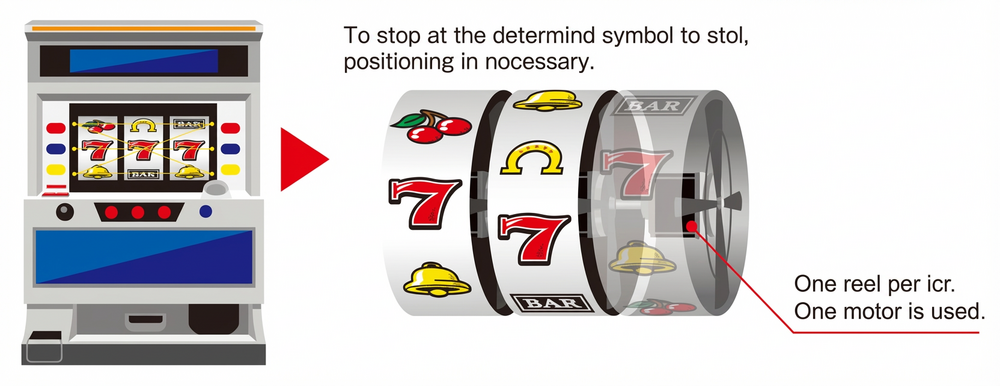

Stepping motors are used in many surprising places in "amusements" that are familiar to everyone. A typical example is "slot machines." Where on earth are stepping motors used in slot machines?

The answer is "reels." Reels are the part of a slot where the three pictures are lined up, and can be said to be the "true protagonist" of a slot game. When the player presses the button, the reels "stop exactly in a set position." Stepper motors are at work to achieve this movement (see diagram below). So stepper motors are in fact responsible for the excitement and suspense that comes with playing slot games.

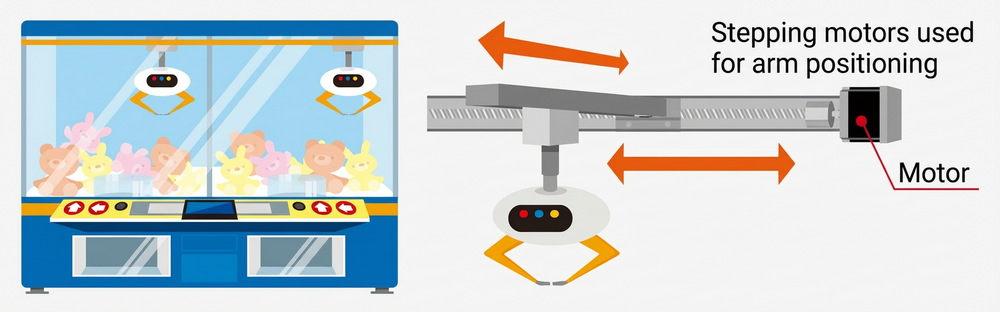

Next, I would like to introduce one more stepping motor used in amusement games: the arms of crane games.

The movement that causes the arm to "move" back and forth and side to side is generated by a stepping motor.

Here again, stepping motors are responsible for what is perhaps the most fun part of crane games.

It's actually a stepping motor that creates that thrilling feeling when the arm stops "abruptly and without delay" the moment you release your hand from the button.

In this way, stepper motors are used not only in industrial machinery, but also in everyday, fun things.

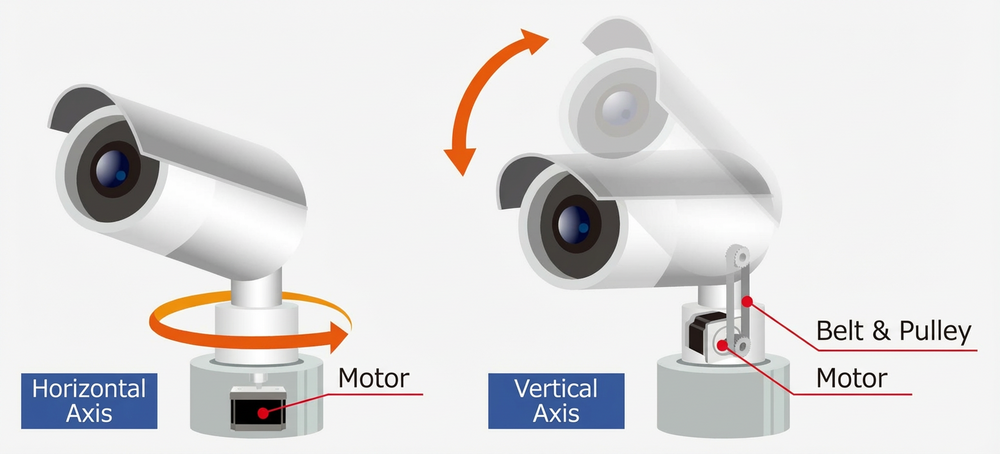

Surveillance cameras keep our towns safe every day. Stepping motors are also used in these cameras, where they exert their power unbeknownst to most people. The motor is in the "moving part (swivel part)" of the camera. Due to the nature of surveillance cameras, some products are required to monitor not only up, down, left, right, but also 360 degrees. Stepping motors are often used for movement and positioning. However, stepping motors have a weakness in that "vibrations become large when rotating at low speeds," so in some cases it may be necessary to use a low-speed machine (gear) or replace it with a servo motor.

What is the industry's leading stepping motor that realizes high speed and low noise in equipment?

What is a stepping motor that maintains torque while solving noise problems?

What is a stepping motor that achieves compact mechanism and improved cycle time?

Customized stepping motor achieves 1.5 times more torque at high speeds

"4-axis integrated closed-loop Stepping Systems" realizes "smooth curves"

Find a high-precision, small stepping motor that can downsize your spectrometer!

The best of both worlds: servos and steps! Quick movement and precise positioning.

Above, we have introduced how stepping motors are used in our daily lives. Although motors are rarely visible to the naked eye, they are likely to continue to be used in many products for a variety of purposes. It might be interesting to look at the products around you and imagine them in action.

公開日: