-

- Free Word Search

Food-related businesses are subject to strict hygiene management standards due to the mandatory HACCP system.

For this reason, food machinery must also take into consideration hygiene in addition to safety and improved productivity.

SANYO DENKI 's stepping motors enable highly accurate positioning and stable speed operation.

In addition, with an abundant lineup of hollow shafts, waterproof and dustproof models, and flexible customization, they can be used widely in food machinery.

This time, we will introduce why stepping motors are recommended for food factories and give some examples of their use.

A stepping motor is a motor that is controlled to rotate a fixed angle each time a pulse signal is input.

By adjusting the frequency of the pulse signal, it is possible to move the actuator to the desired position accurately, achieving high-precision positioning.

As for control, it can be easily rotated by simply turning the driver transistor on and off correctly. The rotation speed can also be easily increased by simply accelerating the ON/OFF timing.

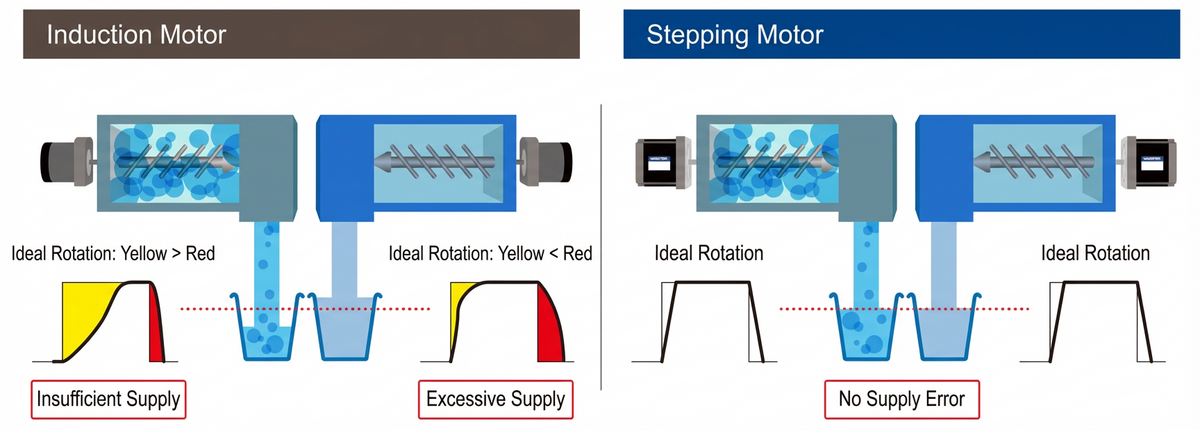

Because it is a synchronous motor, unlike a general-purpose motor (induction motor), it can maintain a constant speed and does not change speed due to the weight of the material, maintaining productivity.

A stepping motor rotates a fixed angle each time a pulse signal is input, allowing accurate positioning without the need for sensors. This eliminates the need for feedback from external sensors, helping to simplify the system.

For more information on how stepper motors work, their types, drive systems, and control methods, please see below.

What is a stepping motor? Explanation of its structure, types, usage (drive system and control method), advantages and features

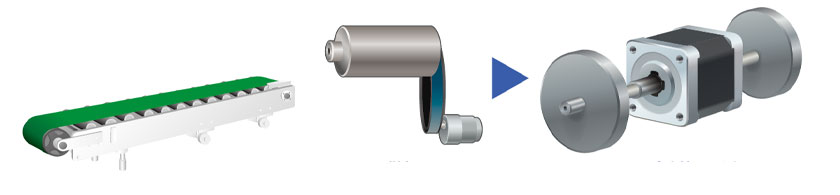

Conventionally, motors were attached to the outside of the conveyor, but by fixing the shaft inside the hollow shaft, the motor can be stored inside the conveyor.

In addition, hoses, liquids, gases, etc. can be passed through the hollow shaft, which allows for space savings through a simplified structure.

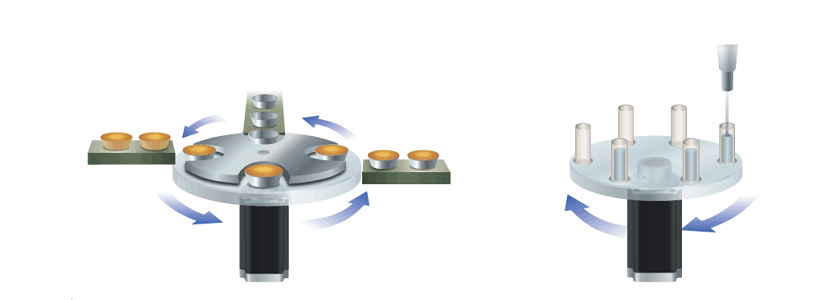

This stepping motor has an allowable thrust load (load that can be applied horizontally to the shaft) that is 37 times* stronger than our previous model, making it suitable for use in applications where a large load is required.

*370N (for 42mm square) compared to 10N for our conventional product

The increased allowable thrust load allows the table to be directly attached to the motor. As the motor cannot directly support the weight of the table, it can simplify the mechanism compared to the conventional gear mechanism or pulley/belt mechanism that drives the table indirectly with a pulley and timing belt. It also eliminates backlash.

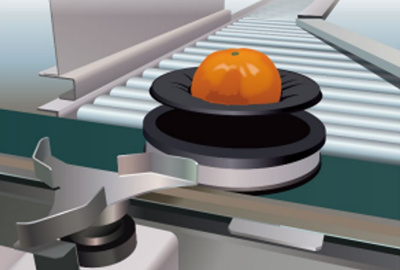

It is also possible to directly drive the sorting table, circular table, etc.

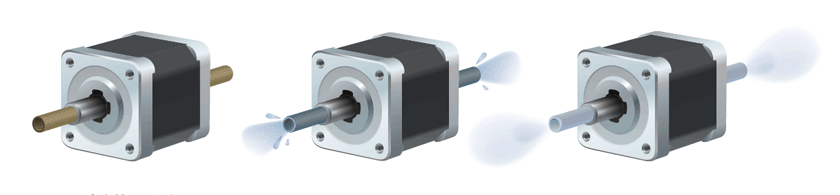

It has excellent waterproof and dustproof performance, and its protection rating is IP65*.

It can also be used in equipment that is exposed to water or powder, such as food-related industrial machinery.

* Shaft and cable tip are excluded. Protection class (IP code) is specified in IEC (International Electrotechnical Commission) 60529:2001.

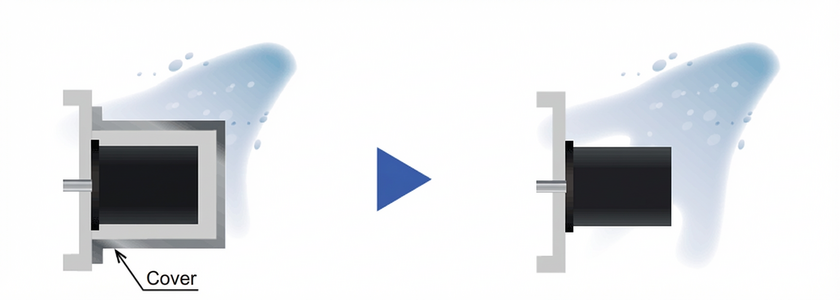

Since the motor is not affected by water, a protective cover is not required, making for a simple system.

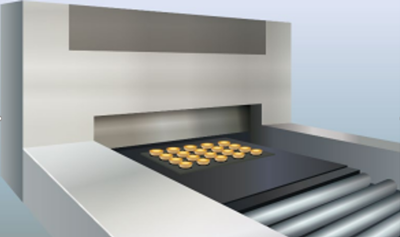

You can safely use it without a cover even on equipment related to foods that use powder, such as bread and cake.

With induction motors, it is necessary to adjust the operating time according to the material and adjust the rotation speed by installing Inverter.

With a stepping motor, stable quality can be maintained even if the condition of the material changes due to changes in temperature and humidity.

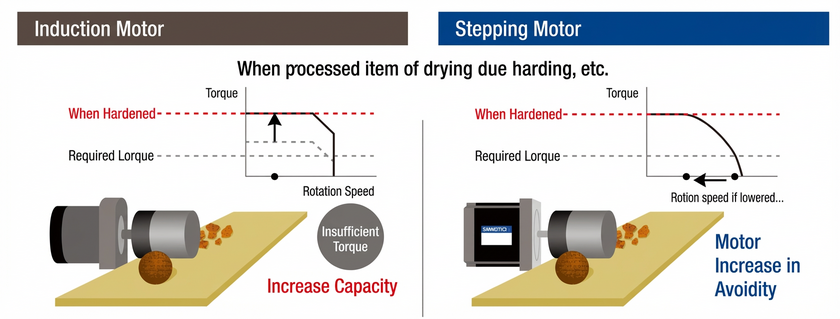

When load fluctuations occur, such as when the processed item hardens due to drying, induction motors require measures such as increasing the motor capacity to take into account the operation during hardening, or increasing the gear ratio to increase torque.

This means that it is costly to increase the motor capacity and requires more space.

Stepping motors provide high torque at low speeds, making it possible to avoid increases in motor capacity due to load fluctuations.

In a mechanism that transports food to a processing facility, when a conventional variable speed AC motor is used, the food will be transported by inertia even when it is stopped when the speed is increased, and friction with the transport belt can cause scratches on the surface of the food.

Stepping motors have good start-up characteristics, which allows for quicker deceleration than AC motors.

There was a need to reduce the tact time for a device that sorts items by size.

Although we replaced the air cylinder with an AC geared motor, we were unable to reduce the tact time, which was an issue.

Stepping motors, which have high torque at low rotation speeds, can move short distances quickly, helping to reduce tact time.

We can proactively propose functional improvements based on our extensive customization know-how. SANYO DENKI 's customization will help you improve the competitiveness of your equipment.

*Customization may be subject to conditions such as minimum lot size. Please contact us for details.

release date: