-

- Free Word Search

Did you know that motors are used in a vacuum environment?

A vacuum environment allows for special processing and manufacturing that cannot be done in the atmosphere, so there are many cases where motors are used in vacuum environments on Earth as well.

In addition, the space business is expected to expand rapidly in the future, and the opportunities for motors to be used in space are expected to increase as new jobs are created, new innovation is promoted, and new products and services are developed that improve our lives.

However, the vacuum environment is completely different from the environment we live in.

This time, we will introduce the types of vacuum environments, applications and precautions for using motors, and examples of customization by our company.

A vacuum is a state of space filled with a gas at a pressure lower than normal atmospheric pressure. Vacuums play an important role in many fields, including science, engineering, and medicine.

In science, it is used in the study of atoms and molecules.

In engineering, vacuum is used to manufacture materials such as semiconductors and solar cells, and to manufacture electronic components.

In the medical field, vacuum is used for tissue research, blood and tissue preservation, and sterilization of surgical instruments.

Vacuum is also an important concept in physics. In classical theory, an absolute vacuum is a state in which there are absolutely no molecules in space. Although outer space is said to be a vacuum, in reality there are trace amounts of molecules in space, so it is merely a hypothetical state and does not actually exist.

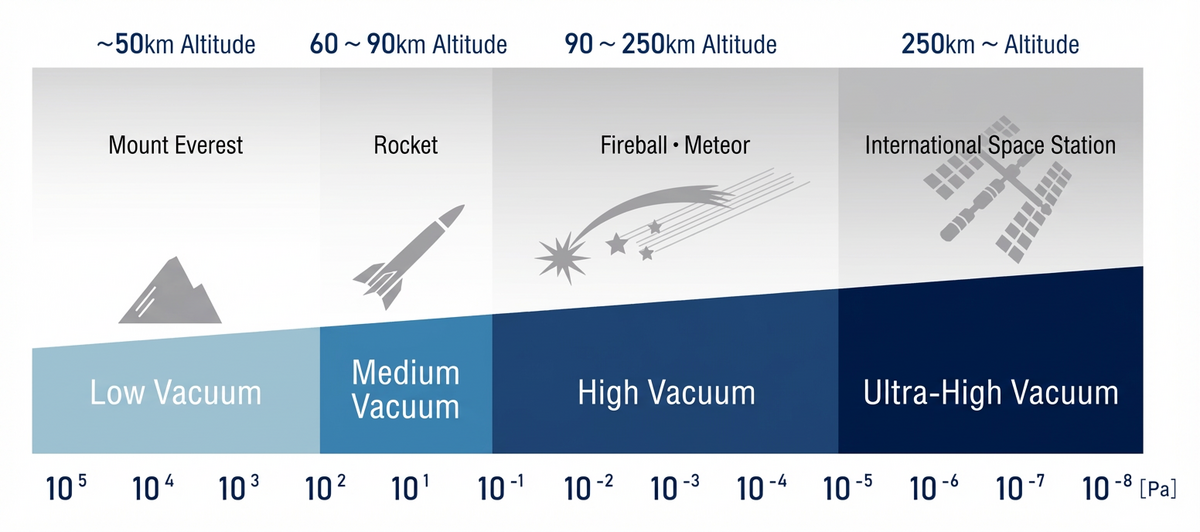

Negative pressure is a state where the air pressure is lower than the standard atmospheric pressure on Earth (near sea level = 1 atmosphere). The JIS (Japanese Industrial Standards) defines four stages of vacuum: low vacuum, medium vacuum, high vacuum, and ultra-high vacuum.

So far we have been explaining about vacuum, but motors are used in devices that take advantage of this vacuum environment and in devices used in outer space.

Vacuum thin-film deposition equipment is used to deposit thin films of metals, ceramics, semiconductors, organic materials, and more.

Thin films are used in a variety of applications, including semiconductor devices, solar cells, displays, and optical devices.

The reason why a vacuum environment is required in vacuum thin-film deposition equipment is to remove air molecules that interfere with the movement of atoms and molecules necessary for thin-film growth.

In a vacuum environment, the low air pressure means that atoms and molecules are less likely to collide with each other, which makes it easier for them to stick to the desired location, resulting in the formation of uniform, high-quality thin films.

Vacuum metallurgy equipment is a device for melting and solidifying metals in a vacuum.

The reason why a vacuum environment is required in metallurgical equipment is:

"By removing impurities from the air, it is possible to suppress the oxidation of metals and the introduction of impurities."

"In a vacuum, the solidification rate of metal increases, making it possible to manufacture metal products with fine and uniform crystal grains."

"The bubbles that form during solidification become smaller, improving the strength of the metal and its quality."

This is because of the benefits it offers.

An accelerator is a device that gives energy to particles such as electrons and protons and accelerates them to high speeds.

Accelerators must operate in a vacuum environment because particles inside the accelerator lose energy when they collide with air molecules.

In a vacuum environment, collisions between the particles and air molecules can be avoided and the particles can be accelerated to high speeds.

Accelerators are used for research in a wide range of fields, including physics, chemistry, biology, and medicine.

It is also used in medical diagnosis and radiation therapy, and is useful in everyday life in applications such as particle beam therapy.

In space, motors are used to operate many pieces of equipment on satellites and spacecraft.

These are just a few examples, but motors are essential devices for the operation of spacecraft and artificial satellites. They perform precise operations while maintaining reliability even in harsh environments, and play an essential role in the success of a mission.

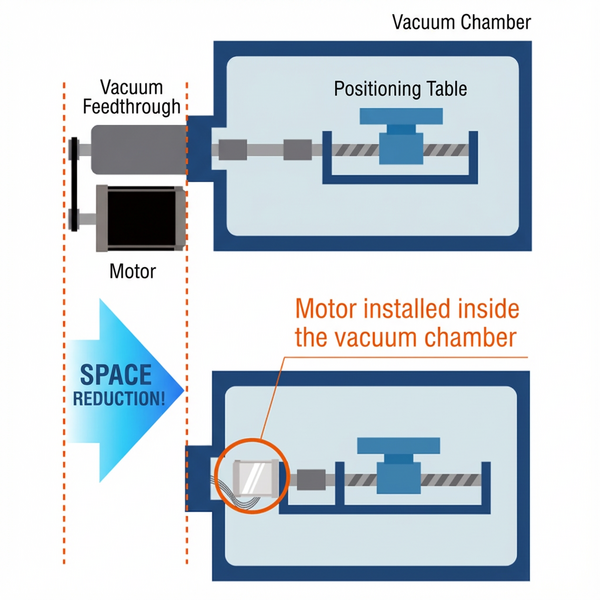

Previously, when using a motor to move an object in a vacuum environment, a vacuum introducer (rotary introducer) was used to transmit the movement of an external motor into a vacuum chamber (a space that maintains a vacuum state).

However, the vacuum introduction machine required a large amount of space, which posed a problem.

Vacuum motors can be installed and used directly in a vacuum environment, eliminating the need for a vacuum introducer and allowing the equipment to be made more compact.

Now, we will explain the precautions to take when using motors under vacuum conditions.

When electricity is passed through the motor windings, the temperature of the windings rises. In the atmosphere, the heat escapes through air convection, but in a vacuum, where there is no air, the temperature rises significantly. For this reason, measures to prevent heat generation are important.

Lubricating oils and cooling oils evaporate in a vacuum. If the evaporating oil diffuses into the vacuum, it will adhere to the surfaces of the vacuum pump and vacuum chamber, leading to reduced performance.

Also, if the lubricating oil evaporates, it will no longer be able to maintain lubrication on the surfaces of components such as bearings and gears.

Furthermore, in standard motors, the flanges and end brackets are made by die casting (a technique in which molten non-ferrous alloys are injected into a mold at high pressure to form a product), but this method leaves tiny air bubbles on the surface, which can lead to outgassing.

Furthermore, when used in ultra-high vacuum environments, we customize the bearings by using solid lubrication (only coating on the inner ring, outer ring, and ball of the ball bearing).

Motor failure in a vacuum environment can cause serious problems, especially in applications where repair or replacement is difficult and extremely high reliability is required.

In a vacuum environment, it is important for motors to produce high torque with as little power as possible, since heat does not easily escape. Therefore, it is necessary to select a highly efficient motor.

Semiconductor manufacturing equipment, electron microscopes, accelerators, synchrotron radiation analyzers, spacecraft robot arms, etc.

42 mm to 86 mm

We can provide fully customized motors to suit your needs. Please feel free to contact us for more information.

The vacuum usage environment varies from customer to customer.

At SANYO DENKI, we can provide a wide range of customizations to meet your needs. Please feel free to contact us for more information.

In cooperation with: SANYO DENKI CO., LTD. Servo Systems Division Servo System Business Group, Sales Division, Design Department 1

公開日: