-

- Free Word Search

The advantage of customization is that it can be applied to a wide range of applications while achieving more advanced control and safety.

This article introduces the benefits and examples of customizing stepping motors.

SANYO DENKI is also good at "customization." We can customize motors according to your requests and quantities, so please feel free to contact us.

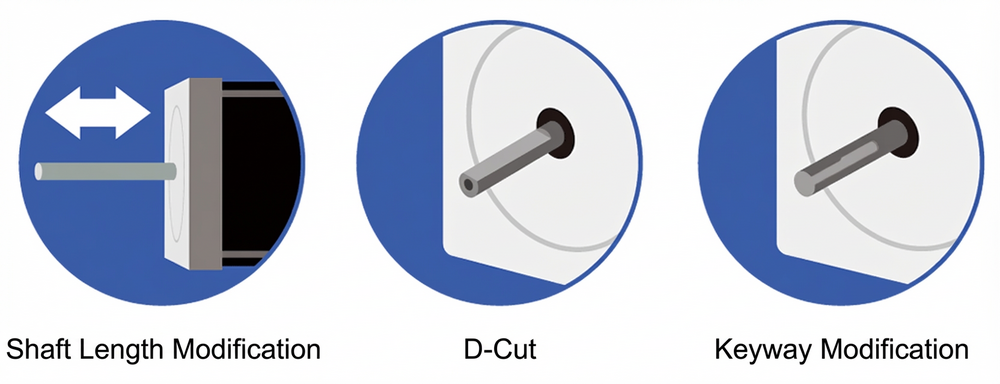

Typical examples of stepping motor shaft processing include "shaft length adjustment," "D-cut," "keyway processing," and "gear installation."

Other processes include gear machining, through-hole machining, and pulley installation.

The motor shaft must fit precisely to connect with other components.

By machining the shaft diameter and shape, it can be precisely aligned with other components and devices and easily attached.

In addition, by machining a keyway into the shaft, axial misalignment with the coupling and transmission loss can be eliminated.

When a customer requires shaft processing, we generally recommend that the shaft is delivered in a customized state. The reasons for this are listed below.

If you perform post-processing on the motor yourself, external force may be applied to the shaft, which may damage the bearings, etc.

Damage to the bearings can lead to abnormal noises when the motor is operating and can also adversely affect the motor's lifespan.

On the other hand, when the manufacturer processes the shaft, this is done before the motor is assembled, so no external forces are applied to the bearings, etc., and the quality of the motor is not compromised.

When installing a motor into a device, it is necessary to connect it to a reducer or coupling, but if the shaft side is delivered in a shape that matches the reducer or coupling, it can be used as is.

By having the manufacturer customize the shaft shape, customers can reduce assembly time and the number of parts they need to purchase. In addition, they no longer need machines or equipment for processing.

Any post-processing done by the customer is not covered by the manufacturer's warranty. If the motor is customized by the manufacturer, the entire motor, including the customized parts, is covered by the warranty.

This is an example of an equipment manufacturer that was aiming to downsize their next model of equipment.

The shaft shape of a standard motor did not fit, which was a bottleneck in making the device more compact.

Therefore, we processed the shaft length and shape to perfectly fit the customer's equipment.

This resulted in a nearly built-in design that can be directly connected to the customer's equipment, which enabled us to make the next model more compact.

Furthermore, the problem of misalignment between the device and the motor was resolved by machining the key groove.

This is an example of a kitchen equipment manufacturer's next-generation oven model.

To keep the temperature inside the oven uniform, it was necessary to use a fan-like blade to circulate the air and eliminate temperature variations.

However, because the inside of the oven is so hot, it was not possible to put a motor inside. So we attached a motor to the outside of the oven and attached metal blades to the shaft to rotate it, but because it was a large oven, the shaft length of a standard motor was not long enough, which caused some problems.

Therefore, we processed the shaft and delivered it to the customer with a length that matched their equipment, thereby achieving the intended movement.

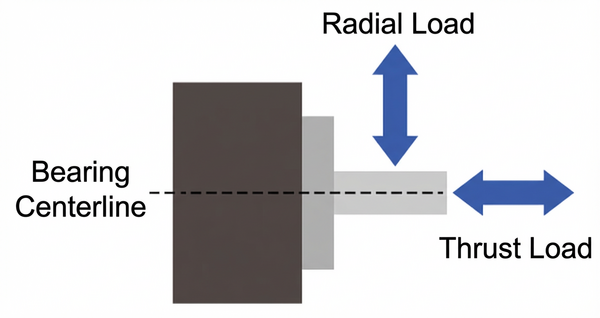

If the shaft is lengthened, the radial load * and thrust load * should be taken into consideration.

* Radial load is a force applied vertically to the center line of the shaft.

*Thrust load (axial load) is a force applied laterally to the center line of the shaft.

In the case of this customer, it was discovered that the radial load would be large because the fan was placed horizontally, so we made the shaft diameter larger to withstand the radial load.

Please feel free to contact us about any issues you may have with customization.

We can proactively propose functional improvements based on our extensive customization know-how.

SANYO DENKI 's customization will help you improve the competitiveness of your equipment.

*Customization may be subject to conditions such as minimum lot size. Please contact us for details.

更新日:/公開日: