-

- Free Word Search

Every year, large typhoons and torrential rains cause great damage in various regions. Power outages are the most frequent damage caused by natural disasters. As disasters become more commonplace due to climate change, an increasing number of companies are embarking on business continuity enhancement plans to protect their operations.

Company A is a manufacturer and seller of bread and confectionery. The company's factory was facing the issue of power outage countermeasures. Mr. E of the Production Management Department of Company A explains as follows:

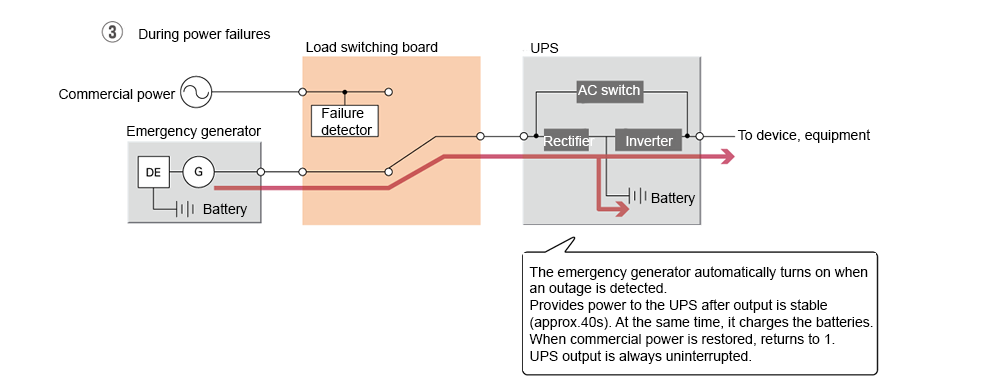

"At our factory, we installed generators as a backup for our commercial ovens. However, we once had a small fire during a power outage. When a power outage occurs, the exhaust system stops, but it takes about 40 seconds for the generator to start up. During that time, the temperature inside the commercial oven rises, causing the oil from the ingredients to vaporize and ignite. When the generator starts up and the exhaust system starts up, oxygen enters the oven, causing it to burn rapidly and break out into a fire. Even if it doesn't actually result in a fire, if the conveyor burns and stops working, the production line will stop and major work such as restarting the machines will be required."

To prevent these risks, it was necessary to continue to supply power without interruption during a power outage and provide backup for at least 20 minutes until the temperature dropped to a safe level.

So Mr. E considered combining an "Uninterruptible Power Supplies (UPS)" with a "generator." However, because the manufacturers of both UPS and generators generally only cover their own products, neither manufacturer would guarantee the operation of the UPS and generator when they were installed separately, which worried him.

Mr. E was looking for a manufacturer that could guarantee the operation of a combination UPS and generator, and was introduced to SANYO DENKI by a trading company he did business with.

After listening to Mr. E's issues, the SANYO DENKI representative proposed the power supply solution "SANUPS-SS."

"It was a solution that provided the optimal combination of UPS and generators, which was exactly what we were looking for. Both the UPS and generators were supplied by a single company, SANYO DENKI, and all of the systems in the lineup had been confirmed to work together, so we felt we could introduce it with peace of mind," said Mr. E.

The power supply solution "SANUPS-SS" has a lineup of UPS models: single-phase 2-wire 100V and 200V models, and three-phase 3-wire 200V models. This time, we selected the three-phase 3-wire 200V models, Uninterruptible Power Supplies" SANUPS E23A" and the generator "SANUPS G53A."

Mr. E then immediately conducted an internal study and confirmed the reliability of the power supply solution "SANUPS-SS."

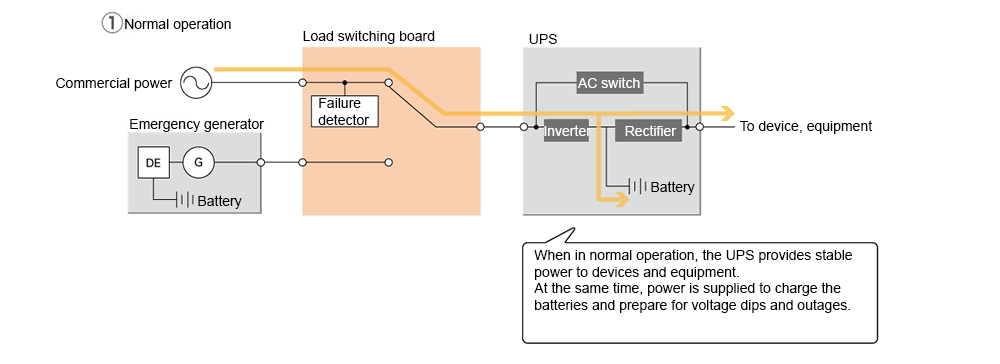

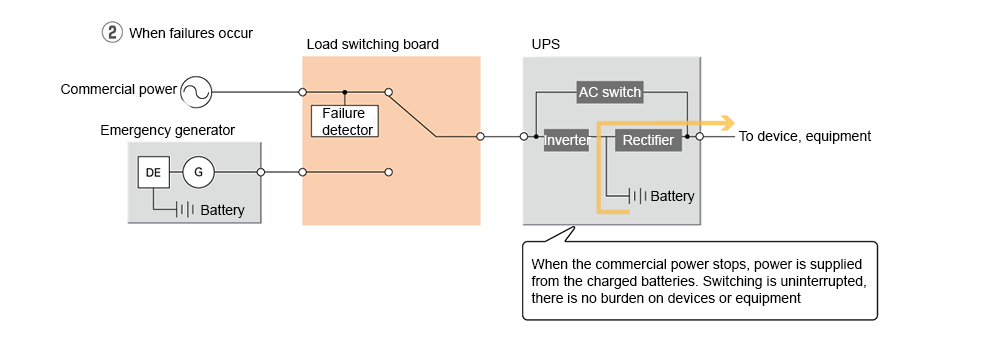

"The SANUPS E23A UPS uses a parallel processing method, and normally it supplies power from the commercial power source while charging the battery. In the event of a power outage or other such event, it switches to battery power supply without interruption and begins backup.

Meanwhile, the generator also starts automatically when it detects a power outage, and once the output has stabilized it starts supplying power to the UPS, and continues providing backup while simultaneously charging the battery. This allows for long-term backup without having to shut down the exhaust system during a power outage." (Mr. E)

*For details about Parallel Processing see Basic knowledge and countermeasures for power outages: UPS with Parallel Processing

Shortly after, Company A decided to adopt the power supply solution "SANUPS-SS" and installed it within its factory.

"Before delivery, we had an on-site inspection at SANYO DENKI 's factory to check that the system was actually working, so we were able to install it with peace of mind. In addition, if you sign up for an on-site maintenance service (*) contract, they will replace any necessary parts during regular inspections, and you can contact them 24 hours a day, 365 days a year if you need help. Both the UPS and the generators have excellent support, so we have been able to use them with peace of mind since installing them. We are also satisfied that we are fully prepared. We would like to consult SANYO DENKI again in the future if we need anything." (Mr. E)

*On-site maintenance services: In order to keep your SANUPS functioning in the best possible condition, we offer a variety of on-site maintenance services to meet your needs. Please contact us for details.

release date: