-

- Free Word Search

|

Customer Profile Company Name Sanko Manufacturing Co., Ltd. Business Contents Manufacture and sale of various blade sharpening machines / Manufacture and sale of whetstones for Sanko sharpening machines / Manufacture and sale of square whetstones URL |

The round blade used to peel meat from bones and slice it is one of the essential tools in food processing. Sanko Manufacturing Co., Ltd., a manufacturer and seller of knife sharpeners, was consulted by a food processing company as to how to sharpen the round blade. Mr. Ishida explains:

"Round blades require sharpening every time they are used, so a huge amount of sharpening is done every day, and someone has to be constantly present at the sharpening machine. Even with technical training, there is inevitably variation in sharpening precision depending on the person. With a labor shortage at the time, we were asked if there was any way to improve efficiency while still maintaining precision."

The company considered automating the equipment, but ran into obstacles due to lack of experience.

"To automate the process, we needed to have a machine that reproduces the techniques of veterans, such as the hand movements that bring the blade close to the sharpening stone and the strength of the lever when pressing down, and choosing the motor and creating the software to achieve this posed challenges for us. We considered asking a cooperating equipment manufacturer to do the work, but this would not only prevent us from building up our own know-how, but would also mean that the product would become that manufacturer's product, and if it was not made in-house, we would have no choice but to outsource after-sales service as well," says Ishida.

The company was determined to commercialize the product as "Sanko Manufacturing Co., Ltd." and was looking for a manufacturer that would support the development.

Sanko Manufacturing consulted with SANYO DENKI, which was exhibiting a 6-axis articulated demo machine at the international food industry exhibition "FOOMA JAPAN," about the issues.

After consulting with SANYO DENKI, they made a comprehensive assessment of Sanko Manufacturing's technical capabilities and proposed that SANYO DENKI, as a supplier, would select the parts and provide a sample program, while Sanko Manufacturing would carry out the actual processing and assembly. In this way, the final product would be "Made by Sanko Manufacturing."

Sanko Manufacturing immediately requested support.

Considering that SANYO DENKI would be providing after-sales service itself, the company provided support to help resolve the problem in as simple a manner as possible.

"The sensation of a person's hand bringing the blade close to the sharpening stone was reproduced by a four-axis drive, with a mechanism for pressing added to the XYZ axes. Furthermore, the delicate adjustment of the pressure applied by the lever was resolved by limiting the torque with the current value so that it could be pressed down gently. This advice showed the ingenuity that only a motor manufacturer can offer," said Ishida.

The motor's excellent characteristics also contributed to making automation possible.

"The linear drive stepping motor that was selected integrated the stepping motor and ball screw, making it extremely compact. In addition, the up, down, left and right movements could be controlled with a single 4-axis integrated driver and a single small Motion Controller SANMOTION C CS100. As a result, despite its complex specifications it was extremely compact, solving the size issue and making it possible to reproduce the techniques of veterans with simple operations."

The issue of the mechanism for sharpening blades to an acute angle was that it was subject to high loads, and if a motor was directly connected to it, the motor bearings would wear out and be damaged. The motor selected by SANYO DENKI had high load-bearing capacity and was able to withstand the weight even when directly attached. We were able to overcome a variety of issues that we had previously thought were difficult," said Ishida.

Sanko Manufacturing's product development is progressing smoothly thanks to SANYO DENKI 's high-quality motors and thorough support.

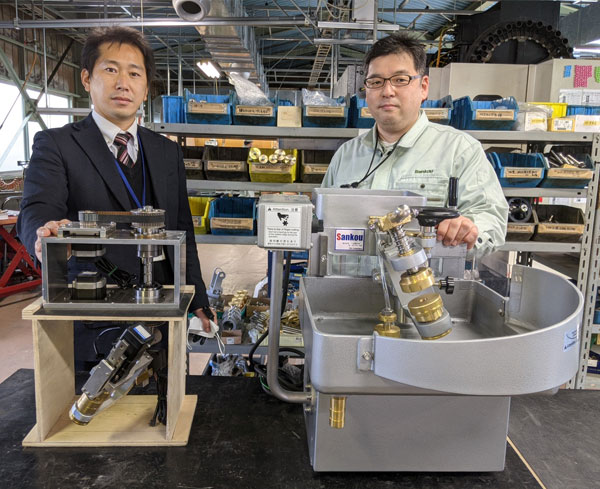

(From left) Mr. Otani of SANYO DENKI and Mr. Ishida of Sanko Manufacturing

release date: