-

- Free Word Search

Company A, a machine parts manufacturer, has been working to reduce manpower and improve efficiency by introducing robots to its factories both in Japan and overseas, but has not seen much progress. Director B of the company's Production Technology Department says the following:

"Outsourcing robot development is too costly, so we used commercially available robots. However, the arm length and detailed movements did not match well, and it was difficult to optimize them for our company's lines. In the end, many processes were done by hand. We have factories overseas, but labor costs overseas are also rising. In order to keep labor costs down, we urgently needed to develop robots that were optimized for our own production lines."

After much trial and error, Mr. B decided to develop an in-house robot that would be optimal for his production line, but he was unable to put his plan into action.

"We concluded that in order to use robots alone to perform the delicate tasks and processes that had previously been performed by humans, the ideal solution would be to in-house manufacture a seven-axis articulated robot, which has more joints than a normal robot. A seven-axis articulated robot has the advantage of being able to achieve movements that are closer to those of a human than a typical six-axis articulated robot. Unfortunately, however, we lacked the technology and know-how to develop robots in-house. We also had the issue of not being able to find a controller that could control up to seven axes. Nevertheless, we were determined to succeed in in-house manufacture of robots at all costs, in order to accumulate technology with an eye to the future." (Mr. B)

Mr. B did not give up on developing robots in-house and continued to gather information.

Mr. B consulted with a person at SANYO DENKI, with whom he had a relationship from purchasing cooling fans in the past. After listening to the issues facing Company A, the person in charge suggested SANMOTION C S500 series Motion Controller, which can control a 7-axis articulated robot.

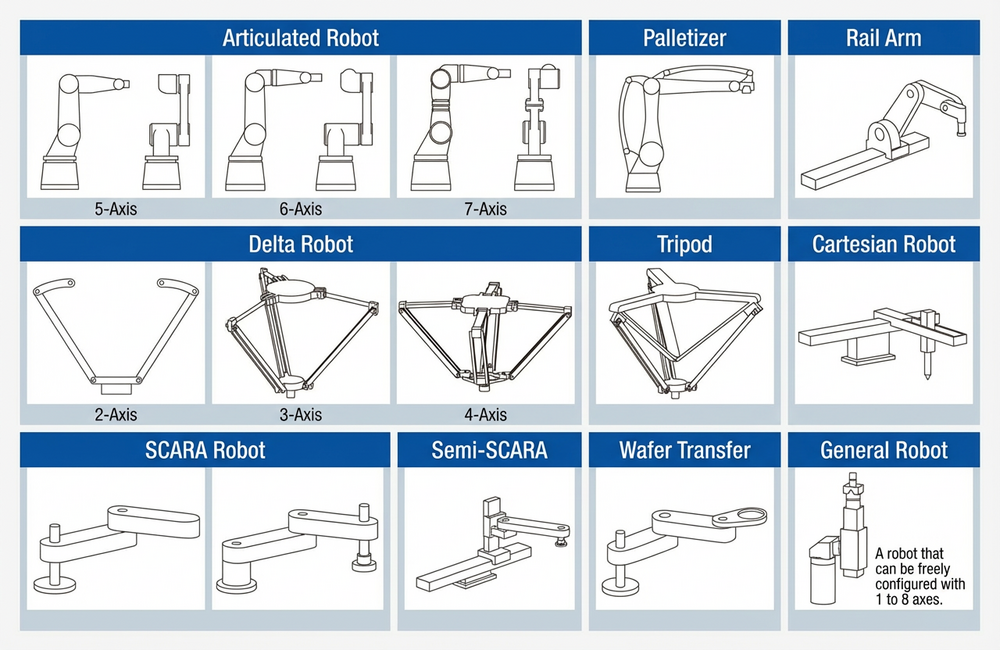

"When I heard that the operation models for Cartesian robots, parallel link robots, SCARA robots, and the like were pre-set, and that programs could be created in a short amount of time without the need for complex input, I had hopes that we might be able to realize in-house development," said Mr. B.

There are 15 types of robot shapes that can be controlled. You can easily realize trajectory control and interpolation movements of various robots.

After multiple design presentations and technical explanations, Company A decided to officially adopt "SANMOTION C", and Mr. B and the other development staff began building a robot using SANYO DENKI 's servo system.

The reason why Company A was able to smoothly make the decision to adopt the company was also due to their trust in SANYO DENKI 's technical support system.

Mr. B and his team's robot development progressed smoothly with the technical support of SANYO DENKI.

"We were worried at first because we didn't have the know-how, but SANYO DENKI gave us great support in designing the joint axis, which was a great help. The robot was completed without any problems, and we were able to successfully adjust the arm length and movement to fit perfectly into our company's production line." (Mr. B)

Company A installed the completed robots on the production lines of each factory, and was able to reduce the number of workers and improve efficiency as expected. Mr. B says that in-house production of robots was significant not only in terms of improving efficiency but also in terms of accumulating technology and know-how.

"By acquiring these skills, our production engineers are now able to apply servo systems to other applications, and we can now consider further labor savings and efficiency improvements. As an aside, the other day a customer who visited our factory praised us for our technical capabilities in in-house manufacturing of robots. I think this is what it means to be an engineer." (Mr. B)

Mr. B's challenge has brought about a variety of secondary effects.

release date: