-

- Free Word Search

In recent years, many factories have decided to install UPS to stabilize the operation of their production lines amid the frequent power outages caused by natural disasters. In particular, food factories are in a rush to take measures to prevent the waste of large amounts of food ingredients every time the line stops, and the associated delays in delivery must be avoided. However, there are many cases where people hesitate to install UPS due to issues such as the installation cost and installation space.

Company A, which manufactures and sells bread and confectionery, was caught up in unexpected trouble a few years ago when a series of power outages occurred. Manager D of the manufacturing department explains:

"Over the past few years, the factory has experienced numerous power outages, which caused the production line for baking ingredients to stop each time, resulting in huge losses. The conveyor inside the baking machine stopped and all the ingredients in the oven were burned, which meant that the ingredients had to be discarded, resulting in a considerable amount of food waste. Every time a power outage occurs, not only does it result in food waste, but it also causes production delays and can lead to missed delivery dates. In addition, cleaning, inspections, and other work to restore the line require a lot of man-hours. And even though the baking machine has safety features, there is still a risk of fire," says D.

Due to the recent increase in disaster-level typhoons, Mr. D predicted that there would be power outages once or twice a year, and so he considered installing Uninterruptible Power Supplies (UPS) as a countermeasure.

"We started by considering a UPS with a constant Inverter system. However, we had to take inrush current into consideration, and found that we would need to install a UPS with a larger capacity than we had anticipated, compared to the capacity of the equipment. This would have meant a 50kVA model, which was expensive and difficult to secure the space to install, so we gave up on that option," said D.

However, further power outages continued to cause losses, and Mr. D was forced to take immediate action.

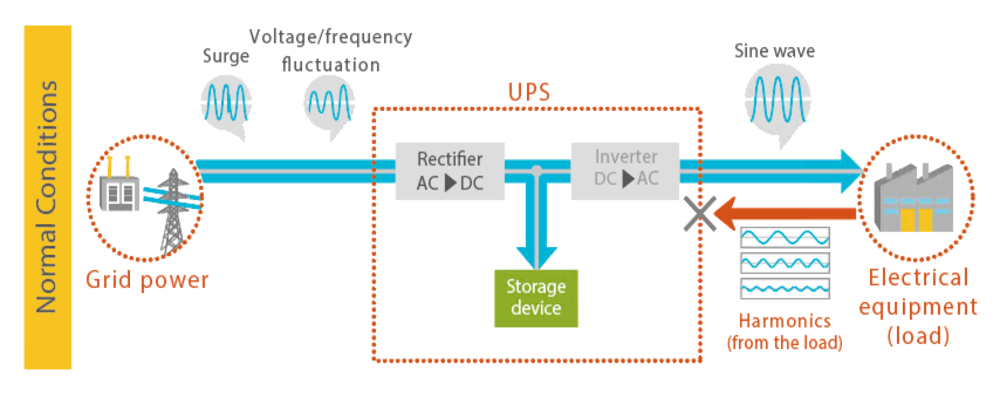

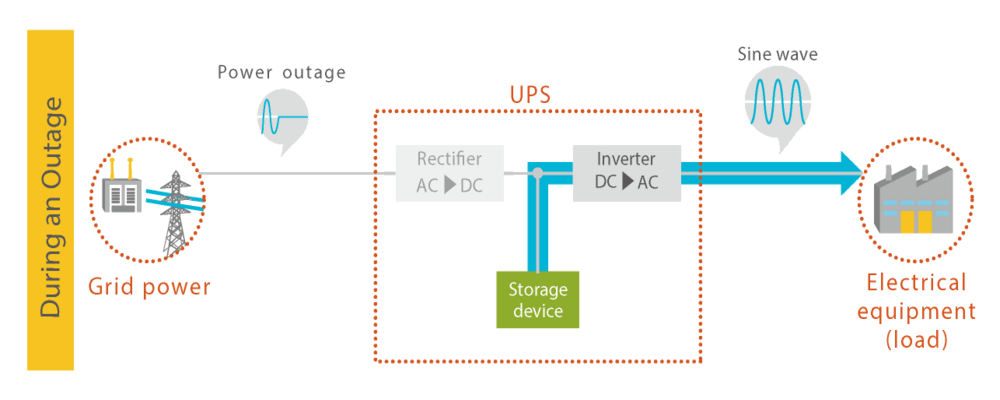

What is the continuous Inverter method?

*For details about Double Conversion Online see Basic knowledge and countermeasures for power outages: Double Conversion Online UPS

*For more information on inrush current, see Basic knowledge and countermeasures for power outages: Power supply problems caused by inrush current and harmonics

Mr. D, who was looking for a solution to back up his baking machine in the event of a power outage, stopped by the SANYO DENKI booth at a production equipment exhibition to discuss his issues. After hearing from Mr. D about the issues facing his factory, a SANYO DENKI sales representative suggested the parallel processing type Uninterruptible Power Supplies" SANUPS E23A."

"According to a SANYO DENKI representative, the parallel processing UPS has strong overload tolerance and can withstand inrush currents, so it can be used with equipment that generates inrush currents, such as compressors and motors. What's more, because there is no need to match the UPS's rated output capacity to the inrush current, the UPS capacity can be reduced. We were also told that by reducing the rated output capacity from what was initially expected, we could reduce the installation space and introduce it at a lower price." (Mr. D)

Mr. D was very interested in the proposal and decided to hear more from the engineers.

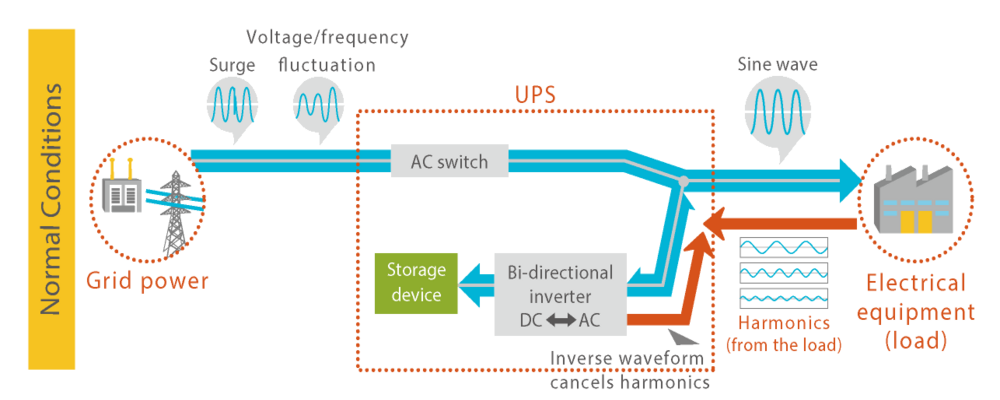

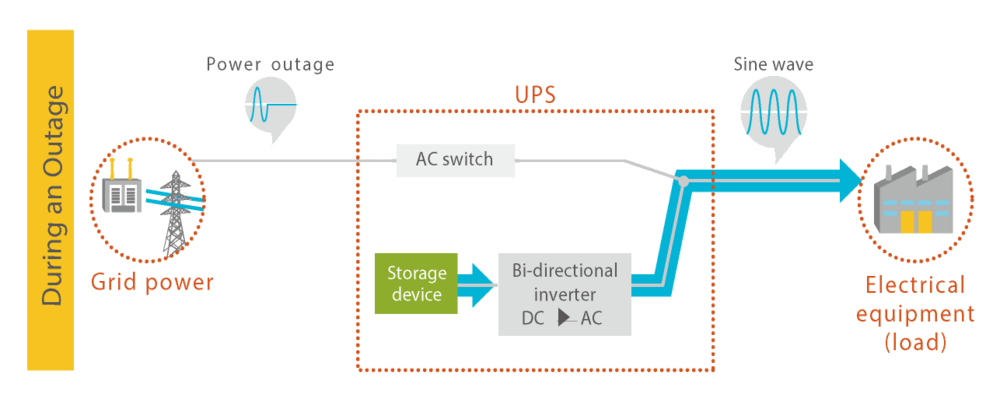

What is Parallel Processing

*For details about Parallel Processing see Basic knowledge and countermeasures for power outages: UPS with Parallel Processing

"Normally, the overload tolerance of a UPS is about 1.25 to 1.5 times the rated voltage, but SANUPS E23A that was proposed to us can maintain an overload of up to 8 times for 500 milliseconds. Therefore, while Double Conversion Online UPS that we were initially considering introducing was 50kVA, the parallel processing UPS can handle just 20kVA. The size of the equipment was also about half, and the price was also cheaper, so we were hopeful that we could introduce it." (Mr. D)

After returning to his company, Mr. D again applied to upper management for the introduction of a UPS. Soon after, Company A decided to officially adopt SANYO DENKI 's Uninterruptible Power Supplies SANUPS E23A.

"We were able to install the UPS before any damage occurred, so we don't have to worry about delivery delays or food waste, and that gives us peace of mind. We were also relegating resources to the man-hours required to restart production, but that is no longer necessary, so we're very satisfied. We're really grateful for SANYO DENKI 's proposal." (Mr. D)

release date: