-

- Free Word Search

When designing equipment, have you ever thought, "I want to achieve precise positioning with simple control!"

There are many cases where using a stepper motor makes it possible to achieve high-precision positioning with simple control.

Furthermore, by making good use of the features of stepping motors, it is possible to improve takt time and enhance product quality.

Let's take a closer look at why stepper motors can achieve high-precision positioning control and some examples of equipment that uses stepper motors.

*This article mainly explains positioning control and usage of stepper motors. For basic information on the mechanism and drive method of stepper motors, please see here.

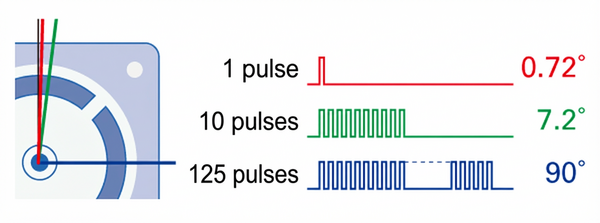

A stepping motor is a motor that is controlled to rotate a fixed angle each time a pulse signal is input.

By adjusting the frequency of the pulse signal, it is possible to move the actuator to the desired position accurately, achieving high-precision positioning.

▼ 5-phase stepping motor (basic step angle 0.72°)

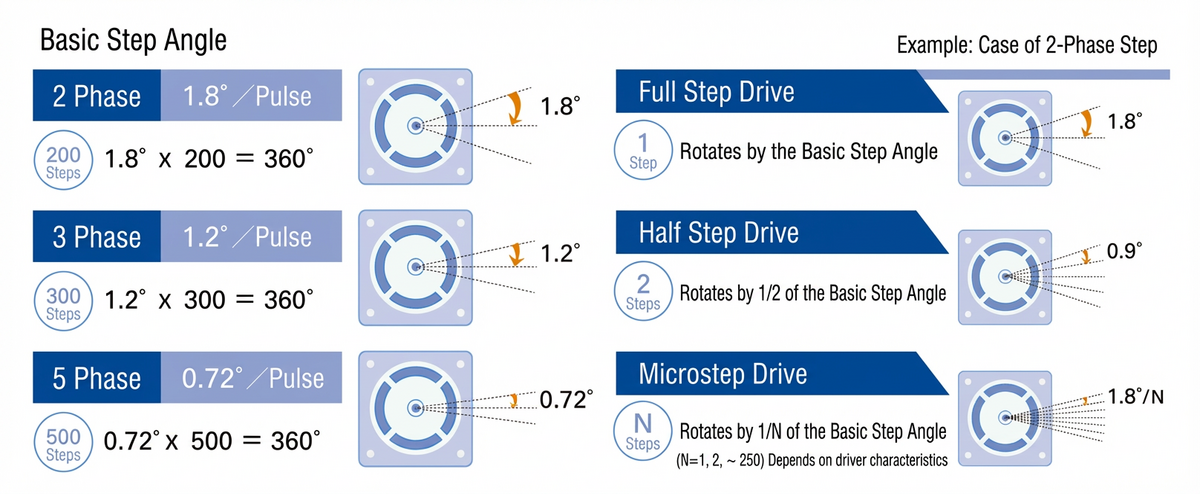

▼The step angle changes depending on the number of phases. The basic step angle can also be divided by driver control.

Stepping motors have a structural feature that uses magnetism to hold the motor position, giving them a strong stopping force (holding torque), making them suitable for devices that require precise, stable stopping.

The servo motor is equipped with a detector and has a feedback function.

Stepping motors use open-loop control that does not require a detector, which allows for simplification and cost reduction of the system.

*In addition to highly accurate positioning, it is also good at quick movement.

For example, because induction motors are induction machines, it takes a long time for the motor to reach the rated speed, which results in poor start-up and delays in starting the device.

Stepping motors have better command response and start-up characteristics.

Stepping motors enable simple, highly accurate positioning control and are therefore used in a wide range of applications, from home appliances to commercial equipment such as printers, industrial machinery such as automatic assembly machines, vending machines, automatic ticket gates, medical syringe pumps and analytical equipment, and amusement equipment.

Closed-loop stepping motors combine the advantages of both motors: they are easier to use than servo motors and more reliable than stepping motors. Their unique control method eliminates the step-out phenomenon that occurs with stepping motors. In addition to eliminating micro-vibrations when stopping, they also greatly reduce positioning time with short strokes. Their simple operation also contributes greatly to cost savings during system construction.

The position detection sensor automatically switches to closed loop control (servo motor control) during rotation and open loop control (stepping motor control) when stopped. This achieves "no loss of synchronism" and "zero micro-vibration" when stopped, contributing to low vibration and improved reliability of the equipment.

Because it has high torque at low speeds, it can shorten positioning time in the field of short strokes and high hit rates.In addition, it has high torque characteristics at low speeds compared to normal servo motors, which allows the system size to be reduced.

Stepping motors can be used for a variety of purposes, including positioning, but they also have issues such as loss of synchronization, vibration, noise, and high current consumption.

We sell stepping drivers that have significantly improved upon the disadvantages of conventional stepping drivers by providing high torque, high efficiency, low vibration, low noise, and comprehensive protection functions. We recommend this product to anyone looking for an easy-to-use stepping driver.

We also have a wide range of motors in various sizes. We also accept various customization requests (※). If you are interested, please feel free to contact us.

*Depending on quantity etc.

For more information about stepping motors, please see "What is a stepping motor? An explanation of its structure, types, usage (drive system and control method), advantages and features."

Supervisor: SANYO DENKI CO., LTD. Sales Headquarters Servo System Business Group

release date: