-

- Free Word Search

Company O, which manufactures and sells commercial kitchen equipment, recently embarked on the development of a new model of commercial induction cooker, but faced several technical challenges. Director E of the Technology Development Department at Company O had this to say:

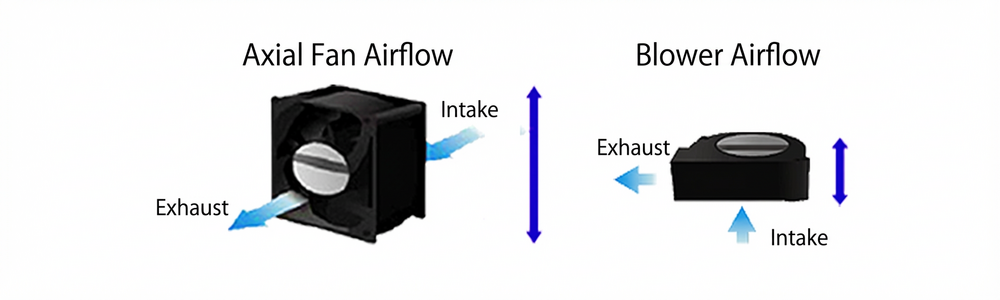

"A prerequisite for the new model under development was that it had to be significantly smaller than the existing model. The induction cooker is equipped with an axial fan to expel heat from inside, but the height of the fan was an obstacle to making it smaller. So, in order to reduce the height of the new model, we tried to reduce the size of the axial fan, but we found that this did not provide sufficient cooling performance." (Mr. E)

Commercial induction cookers need to efficiently cool the heat generated by the magnetic field generating coil. Product failures disrupt the operation of customers' stores and directly lead to reduced sales.

To successfully develop the new model, we needed to find a fan with sufficient performance.

Mr. E, who had been continuing to gather information to solve the problem, visited SANYO DENKI 's booth at an exhibition and consulted with the booth staff about the problem he was facing.

Later, a sales representative from SANYO DENKI visited Mr. E and proposed replacing the axial fan with a blower.

"We found that by switching to a blower, we could significantly reduce the size of the entire equipment. Unlike an axial fan, a blower's intake and exhaust ports are at a right angle, so air is drawn in from the side of the fan. Therefore, by installing the blower horizontally, we could reduce the height of the equipment. Furthermore, the expected lifespan of SANYO DENKI blowers is 40,000 hours(*), so we didn't expect there to be any problems with durability." (Mr. E)

* L10: Survival rate 90% at 60℃, rated voltage, continuous operation, free air condition

Mr. E was so attracted to the proposal that he immediately ordered an evaluation sample and incorporated it into a prototype for evaluation.

"Blowers can send air with high static pressure and in a straight line, so they can cool the heat source directly and efficiently. With previous axial fans, the air was dispersed, so we had to create ducts to guide the air. Not only have we been able to reduce the space required, but we have also cut design labor and material costs. What's more, PWM control function allows us to appropriately control the rotation speed, which is expected to save energy. We've received very positive feedback from within the company." (Mr. E)

In this way, Company O officially adopted SANYO DENKI blower and implemented it in a commercial IH cooker that was under development. As a result, the development was successful according to the specifications originally required, and the new model that was released a few months later was well received in the market.

Mr E. said:

"Thanks to their support, we have received positive feedback from many customers. We have had a long relationship with SANYO DENKI, and we hope to continue to rely on them for advice on various matters." (Mr. E)

For more information about blower fans, please also see "Features of Blower Fans."

release date: