-

- Free Word Search

In the previous article, we introduced Centrifugal Fans. This time, we will take a closer look at Blower Fans.

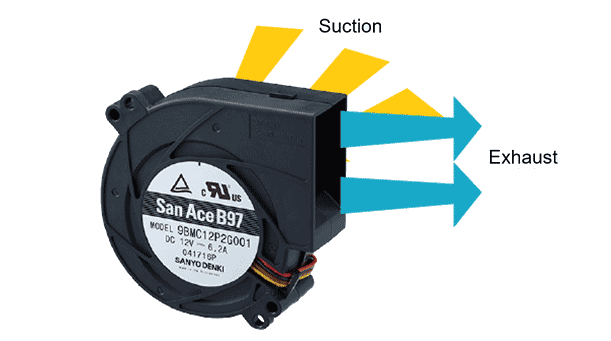

Blower Fans have a structure similar to Centrifugal Fans. They use a rotating impeller to draw in air from the front and discharge it from the side. What makes Blower Fans unique is their spiral-shaped casing, which encloses the impeller. This casing has a single outlet. As the impeller spins, it pushes air outward. The airflow moves along the inner wall of the casing and exits through the outlet.

▲Figure 1: Blower fan structure

Figure 2: Example of ventilation resistance and air volume - static pressure characteristics

By guiding airflow along the inner wall of the casing, Blower Fans can achieve higher static pressure than Axial or Centrifugal Fans of similar size. However, they tend to produce less airflow.

The impeller also features many small blades, which are specifically designed to generate high static pressure.

As shown in Figure 2, Blower Fans have P-Q characteristics similar to Centrifugal Fans, with no stall region and a comparable curve shape.

Unlike axial or Centrifugal Fans, the power consumption of Blower Fans does not fluctuate significantly with airflow. Instead, it tends to decrease as airflow drops and static pressure increases. This means Blower Fans typically consume the most power at maximum airflow.

Sound pressure levels are usually lowest near the middle of the P-Q curve.

Figure 2: Example of ventilation resistance and air volume - static pressure characteristics

With no stall region in their P-Q curve, Blower Fans offer flexible operating points. They are quietest around the center of the curve, which is ideal for noise-sensitive applications.

Blower Fans are known for their ability to generate high static pressure, making them suitable for devices with densely packed components and high airflow resistance.

Since Blower Fans discharge air from a single outlet, they are also well-suited for localized cooling.

Supervised by: SANYO DENKI CO., LTD. Cooling System Design Department

release date: