-

- Free Word Search

装置の用途や性能に合わせて,ファンも特殊な環境に設置される場合があります。山洋電気はみなさまの装置が使われる環境に合わせて,特定の耐久性のあるファンをご用意しています。今回は, 防油ファン・耐温ファン・耐Gファンをご紹介します。

Standard fans are prone to failure when exposed to oil, as it can damage internal electrical components. Oil Proof Fans, however, are designed to withstand such conditions. There are two key differences between Oil Proof Fans and standard models.

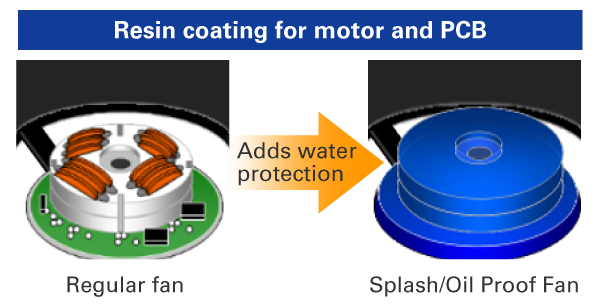

1. The motor and circuit board, which are electrical components, are coated with resin to prevent the ingress of water and oil. (Figure 1)

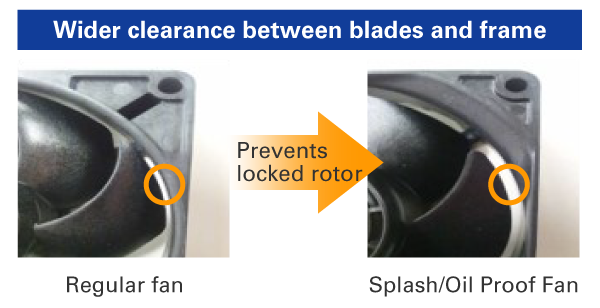

2. To prevent impeller locking caused by oil buildup, the design incorporates a wider clearance between the impeller and the frame. (Figure 2)

▼ Figure 1

▼ Figure 2

Standard fans are prone to malfunction or failure when operated outside their specified temperature range of -20°C to +70°C. By improving thermal durability, these fans can operate reliably even in extreme ambient conditions.

SANYO DENKI’s Wide Temperature Range Fans can operate in extreme conditions, from -40°C to +85°C. This is achieved by designing the internal structure and circuits so that parts affected by cold or heat can work reliably in both environments.

“G” in G Proof Fan stands for acceleration. In equipment like CT scanners, fans are exposed to significant centrifugal forces. Standard fans may not be able to withstand these forces and, in the worst case, could break apart inside the device. To address this issue, SANYO DENKI has developed G Proof Fans that feature a high-rigidity aluminum frame and a one-piece molded structure combining the impeller and rotor cover. These design improvements enhance the bonding strength between components, enabling the fan to endure high centrifugal acceleration.

As shown, there are special environments where standard fans cannot be used. At SANYO DENKI, we have applied our accumulated technologies to enhance the durability of fans themselves. This eliminates the need for additional protective measures on the equipment side, contributing to more compact designs and broader environmental adaptability. If your equipment requires fans that can handle unusual conditions, SANYO DENKI offers solutions tailored to your needs.

Supervised by: SANYO DENKI CO., LTD. Cooling System Design Department

release date: