Ensuring Safety Around Cooling Fans with Finger Guards

- Home

- Knowledge Fan Types and Features

- Ensuring Safety Around Cooling Fans with Finger Guards

Cooling fans operate with rotating blades, which can be hazardous if touched. Safety measures are required to prevent accidental contact by fingers or foreign objects.

Among the various guard designs available, finger guards offer the most effective safety solution while minimizing airflow reduction and increases in noise levels.

In this article, we’ll take a closer look at the features of SANYO DENKI’s finger guards.

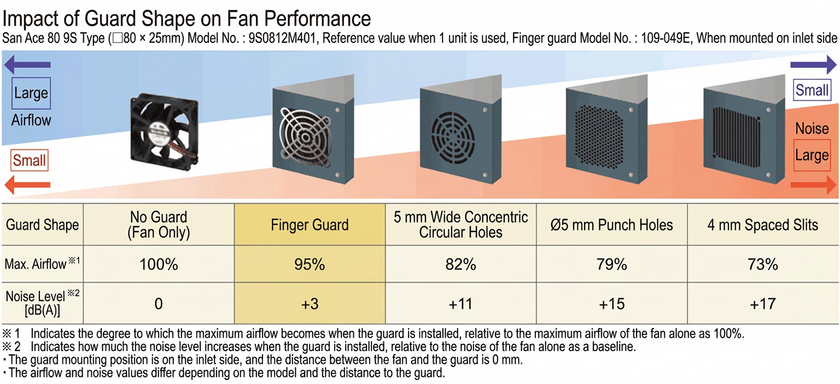

Safety measures to prevent contact between rotating fan blades and fingers or foreign objects include finger guards as well as sheet metal designs with slits or punched holes.

Finger guard

5mm wide concentric holes

φ5mm punch hole

4mm slits

While it may appear that any airflow-friendly design is sufficient, the guard’s shape plays an important role in cooling efficiency and overall performance.

The table below illustrates how guard shape affects maximum airflow and noise levels.

It is evident that guard geometry impacts both airflow and noise. A smaller open area increases airflow resistance, resulting in reduced airflow and higher noise levels.

With guard designs featuring smaller open areas and greater airflow resistance, cooling performance can decline after installation despite selecting a fan for the required airflow, and noise levels may exceed expectations.

Furthermore, raising the fan’s rotational speed to offset reduced airflow results in increased noise and higher power consumption.

By using a finger guard, you can ensure safety without significantly reducing airflow or increasing noise.

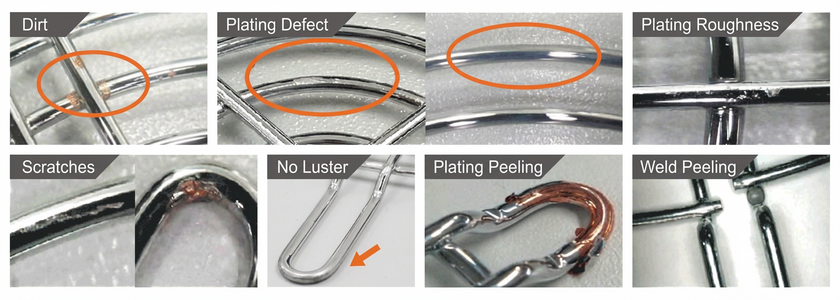

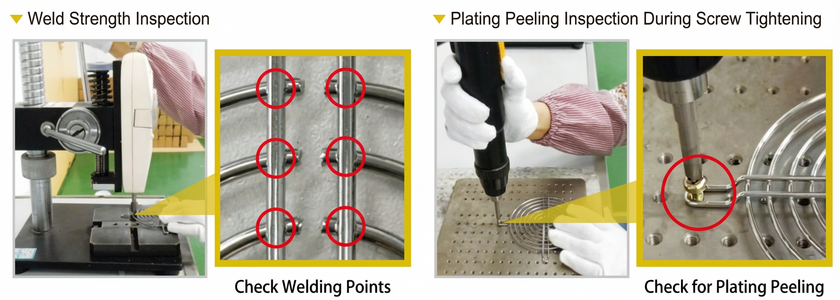

As shown above, finger guards prevent fingers and foreign objects from entering, but if the welds come off, this function is compromised. In addition, if the plating peels, it may enter the equipment and adhere to electronic circuits, causing malfunctions. Scratches or dirt on the finger guard can also affect the equipment’s overall appearance.

At SANYO DENKI, we maintain high quality and reliability by regularly updating jigs and performing process, appearance, and quantity inspections.

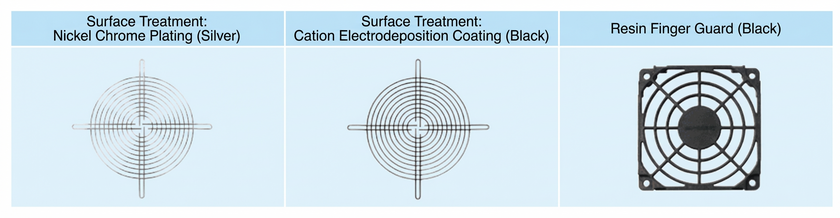

SANYO DENKI provides a lineup of three finger guard types, designed to accommodate diverse environments and design preferences.

Cationic electrodeposition coating provides enhanced corrosion resistance and superior rust prevention compared to nickel-chrome plating. For waterproof fan applications, finger guards with cationic electrodeposition coating or resin-based guards are recommended to ensure durability and reliability.

Finger guards aren’t just for safety—they also influence airflow, noise, and even equipment appearance. Choosing the right guard can help you get the most out of your system, and we offer high-quality options to consider.

Release date: