-

- Free Word Search

So far, we’ve covered the key considerations for selecting a fan. Starting from Section 8, we will explore the unique features of each fan type. Let’s begin with the most familiar type of fan—axial fans.

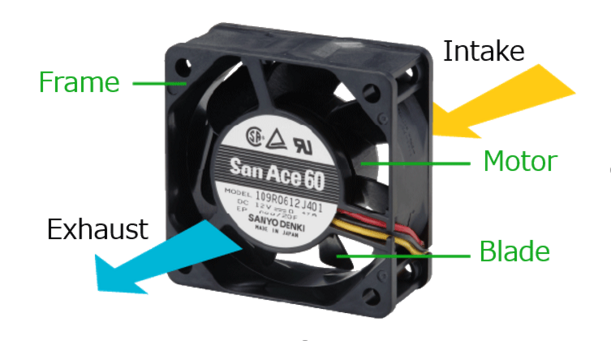

In an axial fan, the motor is mounted on the frame that supports the entire fan, and the blades are arranged around the motor. When viewed from the label side, the blades rotate either clockwise or counterclockwise, depending on the design. In the example shown in Figure 1, air is drawn in from the rear side—behind the label—and pushed out through the front. Since the airflow moves in the same direction as the central axis of the rotating blades, this type of fan is called an “axial fan.”

Figure 1: Structure of an axial fan

The structure of DC axial fans differs from that of AC axial fans.

Figure 3: Example of ventilation resistance and air volume - static pressure characteristics

Axial fans feature an airflow–static pressure curve (P-Q curve), as illustrated in Figure 3. As airflow increases, static pressure decreases, resulting in a downward-sloping curve. A unique feature of axial fans is the presence of a stall region, where the airflow becomes unstable and the curve’s slope changes significantly.

The stall region refers to the area where airflow begins to separate from the blade surface, indicating the onset of aerodynamic stall. On the side of maximum airflow, air moves smoothly along the blade surface. However, as the static pressure increases, the airflow gradually detaches from the surface. This phenomenon is known as "stall."

In the rotational stall region, the airflow over the blade surface becomes unstable, repeatedly attaching and detaching. This marks a turning point where both power consumption and sound pressure levels change significantly.

Figure 2: Example of ventilation resistance and air volume - static pressure characteristics

Axial fans come in a wide range of models featuring high airflow, high static pressure, and low noise, making them suitable for various applications such as ventilation, air circulation, and spot cooling.

When installing an axial fan in a device, positioning the operating point on the maximum airflow side—beyond the rotating stall region—can help reduce both noise and power consumption. We hope these insights will be helpful as you consider incorporating fans into your design.

Supervised by: SANYO DENKI CO., LTD. Cooling System Design Department

Update date: /release date: