-

- Free Word Search

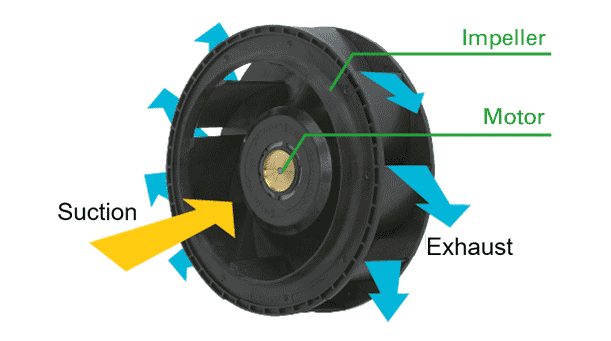

A Centrifugal Fan has its motor placed at the center, with an impeller directly attached to it. Unlike Axial Fans, it does not have a surrounding frame, giving it a simpler and more open structure.

Centrifugal Fans and Axial Fans differ in how they discharge air. While axial fans release air straight in the same direction as the incoming flow, centrifugal fans redirect it by 90 degrees. The spinning impeller generates centrifugal force, pushing air outward from the sides in a radial pattern.

To improve air intake efficiency, centrifugal fans are typically equipped with an inlet nozzle. Separating the intake and exhaust areas allows the fan to draw in air more smoothly and perform at its full potential.

Figure 1: Structure of Centrifugal Fan

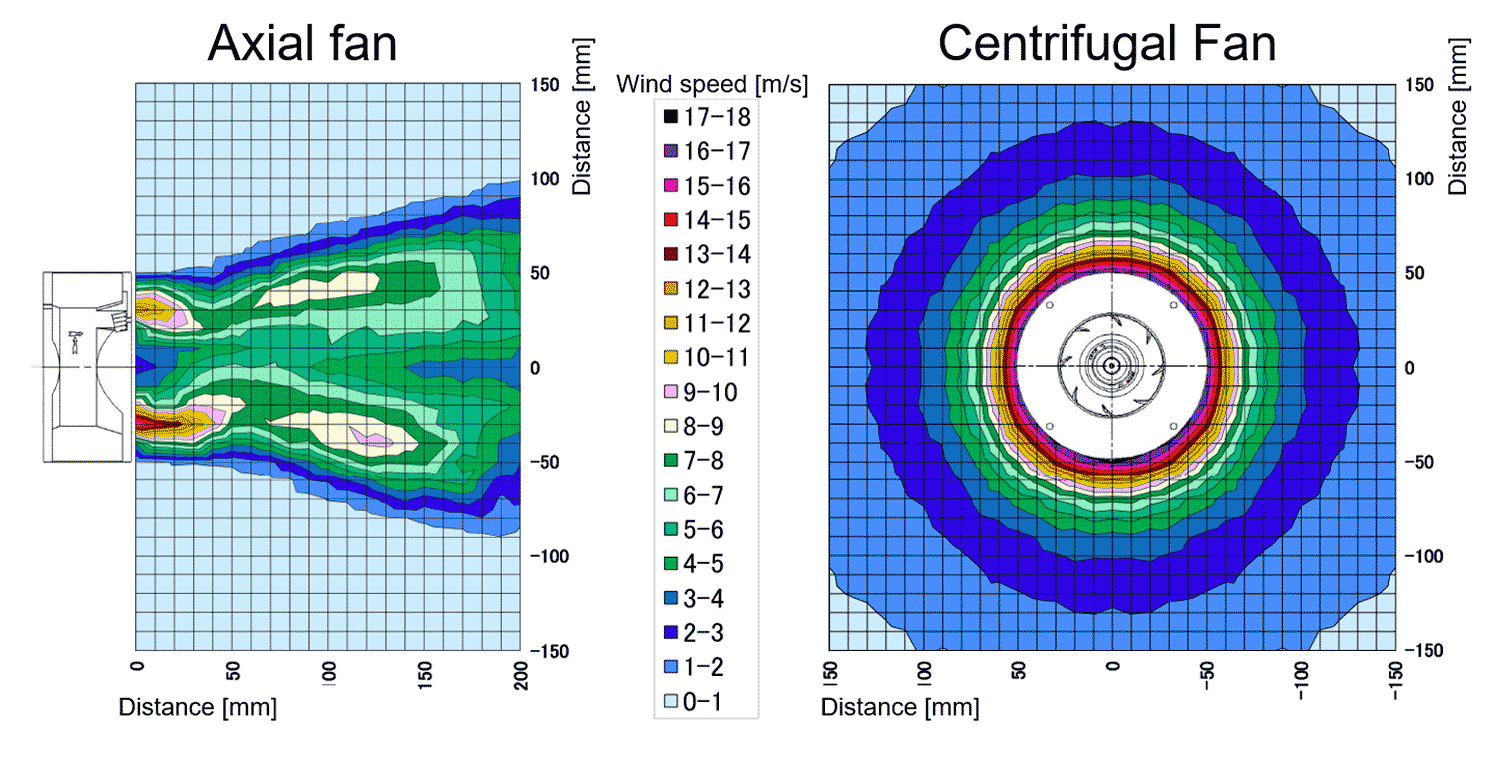

▲Figure 2: Comparison of axial fan and wind speed distribution

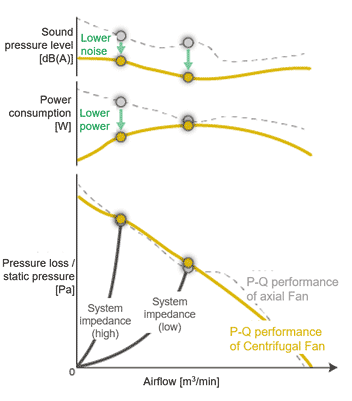

Figure 3: Example of ventilation resistance and air volume - static pressure characteristics

Due to the different internal structure, centrifugal fans lack the stall region with a flat P-Q curve seen in axial fans. Instead, their P-Q curve is nearly linear. Power consumption and sound pressure level curves vary by model.

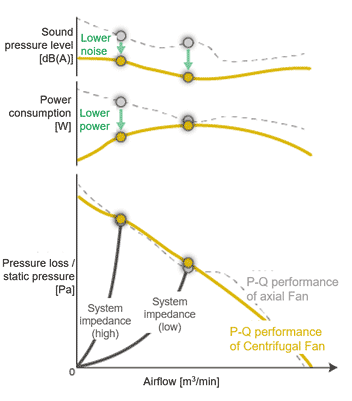

Figure 3: Example of ventilation resistance and air volume - static pressure characteristics

The absence of a stall region in the P-Q characteristics allows centrifugal fans to operate effectively across a wider range of conditions compared to axial fans, especially under varying airflow resistance. Depending on the model, they may also run more quietly and consume less energy at the same operating point.

With their ability to generate high static pressure and support strong airflow intake, centrifugal fans are ideal for circulating air throughout large systems. Common applications include ventilating large equipment interiors and assisting heat exchangers.

Supervised by: SANYO DENKI CO., LTD. Cooling System Design Department

release date: