-

- Free Word Search

The life expectancy of a fan can significantly affect the overall lifespan of a device, as the durability of its internal components is influenced by temperature. If the fan’s lifespan is shorter than that of the device, it may need to be replaced as part of regular maintenance. In Lesson 3, we’ll take a closer look at fan life expectancy.

Generally, the expected life of a fan is defined by its ability to operate continuously over a certain period without a significant drop in airflow performance or a noticeable increase in noise.

The catalog defines the fan’s life expectancy as follows:

“90% survival rate” and “L10” both refer to the duration during which 90% of the fans in a given group continue to operate normally. In other words, both have the same meaning and define a lifespan with 90% reliability.

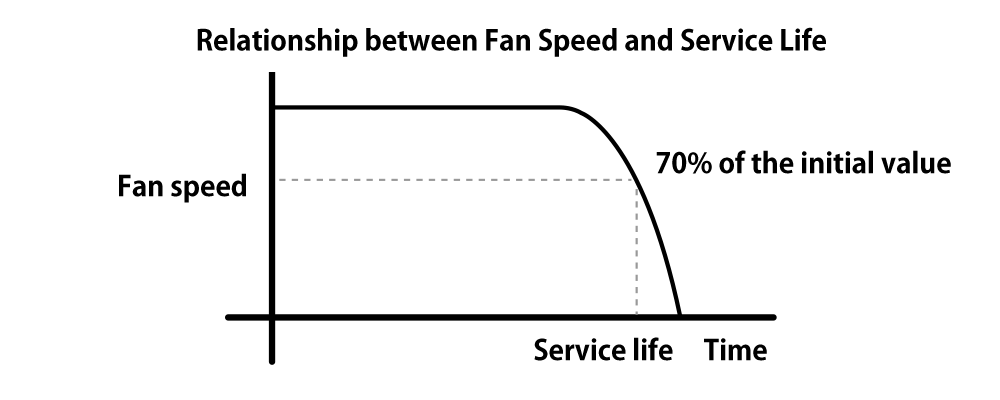

SANYO DENKI defines “life” as the amount of time a fan can operate before its rotational speed drops to 70% of its initial value. This value is used to determine when the fan’s airflow has decreased enough to potentially affect its performance.

■ Relationship between rotation speed and fan lifespan

The number of components in a device directly influences the factors that affect its overall lifespan. In some approaches, this lifespan is defined by the MTBF (Mean Time Between Failures) of its electronic components.

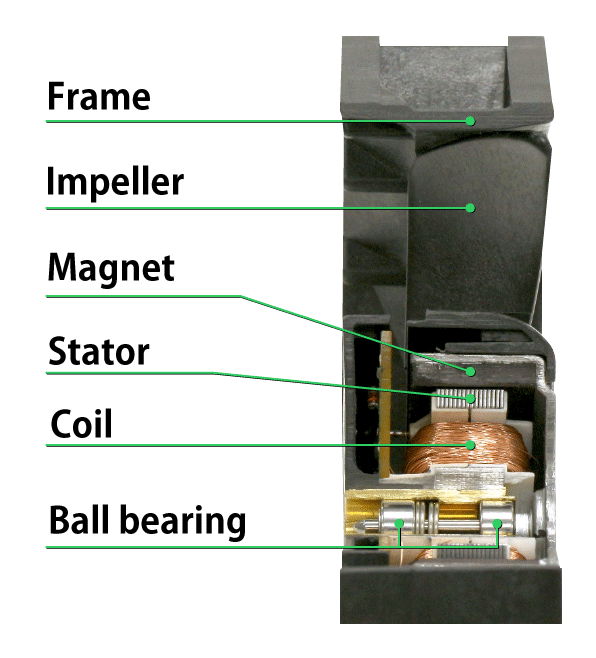

For fans, however, it is not the electronic components but rather the structural parts—specifically the bearings in the motor that drives the blades—that have a greater impact on lifespan. Although various types of bearings exist, SANYO DENKI uses only high-reliability "ball bearings" in all its fans to ensure stable performance and long-term durability.

There are two types of ball bearing life: "fatigue life" and "grease life."

Unlike industrial motors, fans typically place relatively low stress on their bearings, so fatigue life is rarely an issue.

Therefore, the grease life of the ball bearing becomes the most critical factor in determining the overall lifespan of a fan.

Since a fan’s lifespan is determined by the grease life of its ball bearings, extending the grease life directly leads to a longer life expectancy of a fan. There are four main ways to extend this grease life.

1.Reducing bearing temperature

2. Reduction of bearing load

3. Improvement of grease

4. Improved load capacity of bearings

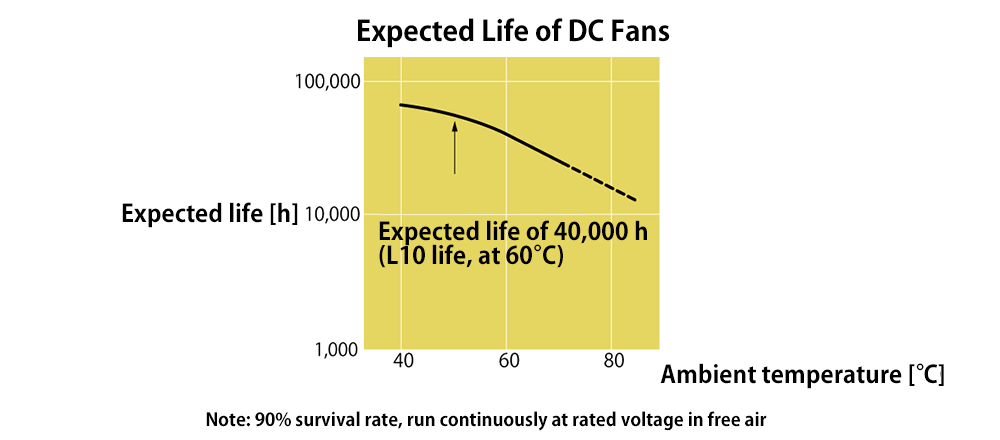

Since points 2 through 4 are determined during the fan’s design phase, users have limited ability to modify them. However, point 1,― "reducing the bearing temperature," ― can be addressed by lowering the ambient temperature around the fan, which produces a similar effect. For example, a fan* rated for 40,000 hours at 60°C will last approximately 70,000 hours when operated at 40°C.

*For San Ace model: 9GA0312P3K001.

Fans are primarily used for cooling, however; it is important to recognize that the fan itself is also affected by ambient temperature. Keeping this in mind helps users choose the right fan and reduce maintenance needs.

The grease life of a bearing is the most significant factor affecting fan's expected life. Therefore, SANYO DENKI implemented various design strategies to extend grease life—such as reducing bearing temperature and minimizing bearing load.

For example, changing from a resin frame to an aluminum frame with better heat dissipation helps reduce the temperature increase in the bearing, resulting in lower overall bearing temperatures.

This lesson covered the basics of fan life expectancy. In addition to expected lifespan, many people tend to compare the values for maximum airflow and maximum static pressure when selecting fans for cooling or ventilation. However, once installed in a device, a fan cannot simultaneously achieve both maximum airflow and maximum static pressure.

In the next lesson, we’ll take a closer look at the relationship between airflow and static pressure—referred to as the fan’s airflow-static pressure characteristics.

Supervised by: SANYO DENKI CO., LTD. Cooling System Design Department

release date: