-

- Free Word Search

Company N, which develops and manufactures various types of medical equipment, was developing a new model of imaging diagnostic equipment.

"Diagnostic imaging equipment is an important medical device that is essential for the early detection of disease and locating the location of lesions by imaging the state of the inside of the body. Naturally, high performance is required, but quietness is also important because it is used near patients. Therefore, we have been developing products that can be differentiated by reducing noise and can be brought to the market."

Mr. A selected several fans from a fan catalogue that had lower sound pressure levels than his current models.

"When actually installed in the equipment, the noise level changes depending on the layout of the parts inside the equipment. When we installed the fan we selected this time and measured the sound pressure level, it was quieter, but none of them satisfied the cooling performance." (Mr. A)

Because the selected fans had to be installed and measured one by one, Mr. A was racking his brains over how to select a fan that would be both quiet and have good cooling performance within the limited time available.

Mr. A, who was having trouble selecting a fan, consulted a SANYO DENKI representative about his current issues.

Later, a sales representative from SANYO DENKI visited Company N and measured the ventilation resistance of the imaging diagnostic equipment currently under development using an Airflow Tester he had brought with him.

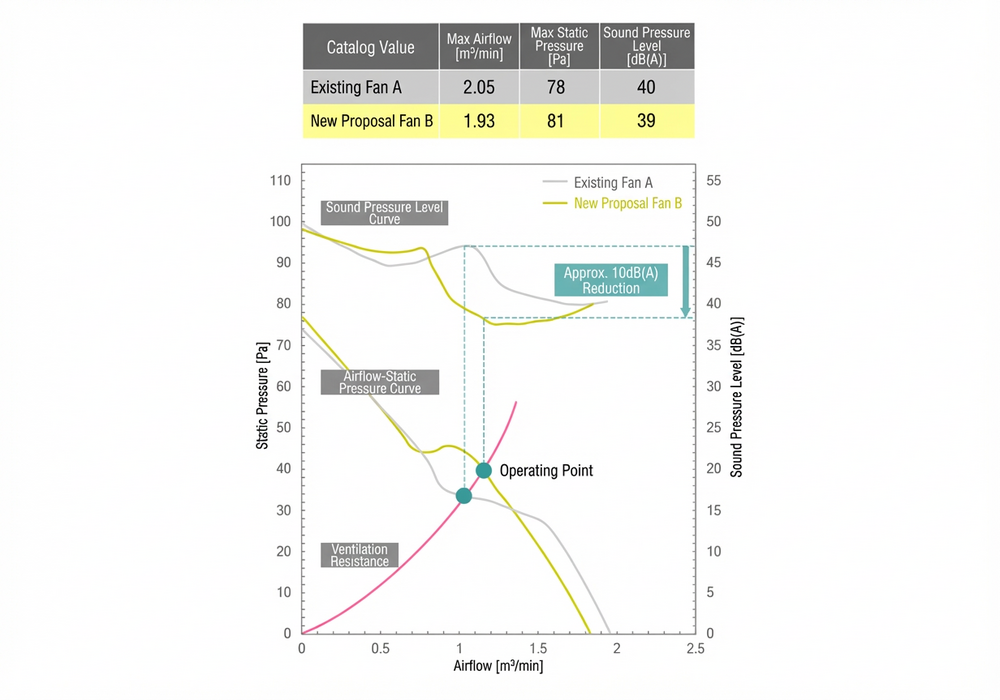

"To select the optimal fan, you need the ventilation resistance of the device(*). The intersection point between the ventilation resistance and the fan's airflow-static pressure characteristics is the operating point of the fan when installed in the device. If you know the operating point of the fan, you can determine the airflow, static pressure, and sound pressure levels when installed." (SANYO DENKI representative)

The SANYO DENKI representative took the measurement results home with him and later visited N Company again to propose a fan.

"SANYO DENKI proposed us a new fan, type B. The catalog values indicated that the performance of the current fan, type A, was superior, but they explained to us that at the actual operating point, fan B had a larger air volume and static pressure, and could also reduce the sound pressure level." (Mr. A)

After receiving the proposal, Mr. A immediately requested a sample and evaluated the actual equipment. As a result, the noise level dropped by 10 dB. Company N then decided to adopt the proposed fan, and was able to move forward with commercializing the new model of diagnostic imaging equipment, which achieved a significant reduction in noise.

* Ventilation resistance: The difficulty of air flowing inside the device. Also called system impedance.

After hearing this proposal, Mr. A became interested in the "Airflow Tester" that enables optimal fan selection.

"The development period was shortened thanks to the Airflow Tester measuring the ventilation resistance of the equipment. This allows us to select fans efficiently based on accurate measurements, rather than relying solely on actual equipment evaluation as in the past. It was decided within the company that this could be used for future chassis designs, and so the decision was made to introduce it. I would like to make use of the Airflow Tester in future developments." (Mr. A)

For more information about Airflow Tester please also see "Fan Airflow and Static Pressure."

release date: