-

- Free Word Search

Company C, a communications equipment manufacturer working to improve the communications environment in South Asia, has begun developing communications infrastructure in anticipation of the spread of 5G. 5G will enable faster, larger-volume communications than previous generations, but more advanced information processing means more heat is generated, making the creation of a new cooling system a challenge. Manager F, in charge of development at Company C, explains:

"There is still a lot of 3G equipment in Asia and Africa, so we are rapidly replacing it with equipment that is compatible with 4G and 5G. Our previous 3G-compatible equipment used four axial fans, but 5G tends to generate more heat, so we needed a more powerful cooling system. However, we had to reduce the number of parts, and our superiors asked us to reduce the number of fans. In addition, because the equipment will be installed outdoors, we also had to consider measures to prevent corrosion of the fan circuit boards, so we had a mountain of headaches," said Mr. F.

Mr. F was looking for a cooling fan that could overcome these difficult challenges.

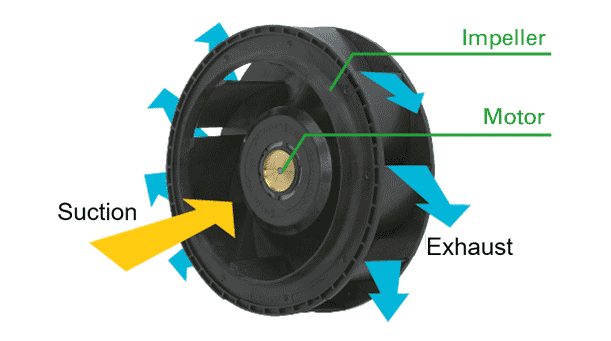

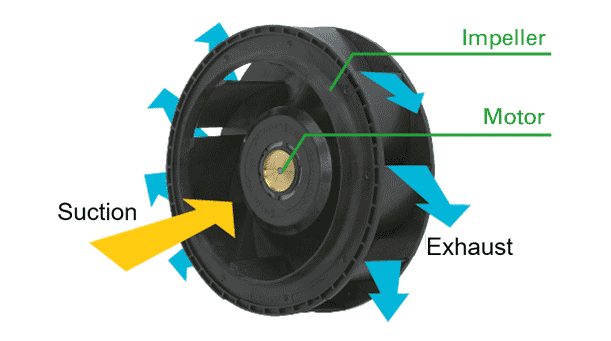

▲Structure of Centrifugal Fan

Mr. F, who was looking for a cooling fan that could handle the increasing amount of heat generated, consulted SANYO DENKI, which did business with other departments, about the problem and was suggested Centrifugal Fan.

"We were very excited to hear that two Centrifugal Fan Centrifugal Fan could provide the cooling performance of the four axial fans that we had previously been using. Initially, the development team had not thought of using centrifugal fans, but we discovered that they combine high airflow and high static pressure, making them ideal for cooling large, densely packed equipment such as communications equipment and servers." (Mr. F)

▲Structure of Centrifugal Fan

For more information about Centrifugal Fan see Knowledge Fan Basics: Characteristics of Centrifugal Fan

Upon receiving Mr. F's request, SANYO DENKI immediately arranged for samples to be sent to Company C. Company C confirmed that two units would provide sufficient cooling performance as proposed.

"In addition, SANYO DENKI 's designers provided technical support. One of our concerns was the corrosion prevention measures for the fan circuit board, and they customized the fan by applying a moisture-proofing material. They also helped us extend the lead wires and expand the voltage range," said Mr. F.

Company C was satisfied with the customization and thorough support, and soon decided to officially adopt the system.

"Using Centrifugal Fan had never occurred to me before, so this was a new discovery for me. SANYO DENKI properly understood our requirements and provided us with the optimal solution. I look forward to consulting with them again in the future." (Mr. F)

For more information about Centrifugal Fan please see "Characteristics of Centrifugal Fan ".

release date: