-

- Free Word Search

Company A deals with communication devices, control devices, power supplies, etc. When embarking on the development of a new communication device terminal, they also needed to improve the issues that their previous models had. Director H of the development department said the following:

"With conventional equipment, there were cases where foreign matter such as dust and dirt would adhere to the filters in the ventilation holes, and in products for outdoor use, there was the possibility of fallen leaves and other particles adhering to the holes. When foreign matter adheres to the ventilation holes, the airflow decreases, and depending on the severity, there was a risk of heat problems occurring. For this reason, we selected fans that were deemed to have sufficient cooling performance based on the catalog specifications. However, there were cases where over-specification caused noise problems, so we needed to reconsider our evaluation methods. Therefore, we thought that if we could quantify the airflow of fans when installed, while assuming a variety of conditions, it would lead to more appropriate housing designs and fan selections, even at an early development stage."

However, attempting to quantify the air volume presented more difficulties than we had imagined.

"We considered running a simulation, but the implementation costs were high and we didn't have any staff with the know-how, so we gave up. We then tried measuring the airflow using a commercially available anemometer, but the airflow speed of the fan varies greatly depending on the measurement location, and we were concerned about the accuracy of measuring the airflow in the limited time available," said Mr. H.

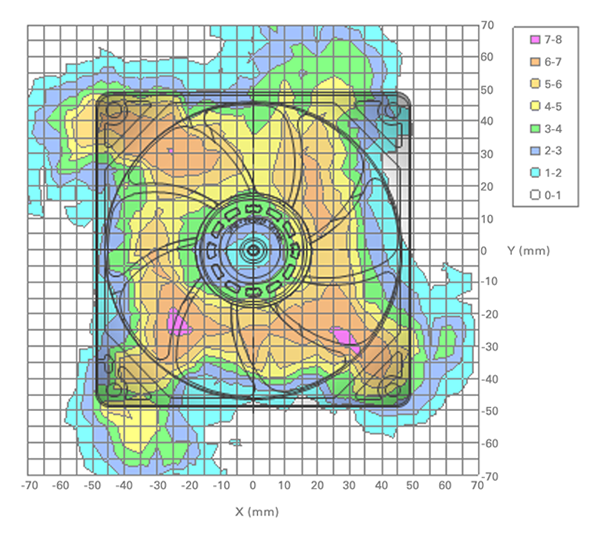

*Example of fan wind speed distribution

Company A, which was stuck trying to quantify the airflow, watched a seminar called "How to Choose the Best Fan" held by SANYO DENKI. They became interested in the "San Ace Airflow Tester" that was introduced in the seminar, and consulted SANYO DENKI.

"A SANYO DENKI representative gave us a detailed explanation of how it was possible to easily measure things like the fan's operating airflow and the ventilation resistance of the device. After the explanation, we tried out some measurements using a demo unit, and found that it was easier to obtain highly accurate measurement results than with an anemometer," said Mr. H.

After confirming that it was possible to measure the fan's operating airflow easily and with high accuracy, Mr. H soon decided to introduce it.

Mr. H had this to say about the benefits of using the San Ace Airflow Tester:

"By measuring the airflow during operation, we were able to collect data on the airflow under a variety of assumed conditions, such as when foreign objects are attached, when a protective cover is installed, or when the shape of the ventilation holes is changed. By using the measured data, we can now design the housing and select fans based on an environment that is closer to reality," says H.

Mr. H explains that there are many other benefits to using the San Ace Airflow Tester.

"By measuring the ventilation resistance of equipment and obtaining the data, we can verify the ventilation resistance when changing the ventilation hole filters or the component layout inside the equipment. In addition, by calculating the operating point from the measurement results, we can estimate whether cooling is possible, which may enable more appropriate fan selection. We believe that being able to obtain data that could not be quantified until now will be useful in various ways for future equipment development." (Mr. H)

For more information about Airflow Tester please also see "Fan Airflow and Static Pressure."

release date: