-

- Free Word Search

Factories that manufacture semiconductors, the most precise electronic components, use a lot of highly advanced precision equipment that requires the utmost precision compared to factories in other industries. These devices are sensitive to even the slightest fluctuations in power and changes in environmental conditions, so strict environmental management is required. For this reason, the stability and reliability of the power supply in semiconductor factories is extremely important, and there is a risk that even a slight voltage drop can lead to expensive losses.

This article looks at typical backup targets in semiconductor factories, such as semiconductor manufacturing equipment, large-scale backup targets such as line floors, and instrumentation systems, and provides a detailed explanation of the UPS suitable for each, as well as the performance and functions required.

There are many types of semiconductor manufacturing equipment used in each process of semiconductor manufacturing, totaling approximately 170*1. Semiconductors are famous for the large number of manufacturing processes, and each process also uses a large number of semiconductor manufacturing equipment.

*1Calculated by our company based on the "Semiconductor Manufacturing Equipment Classification Table" from the Japan Semiconductor Equipment Association.

Semiconductor manufacturer factories have many semiconductor manufacturing devices, and even if a problem occurs with just one of these devices, it can result in losses such as defective lots.

For semiconductor manufacturing equipment, the SEMI standard (SEMI standard, SEMI international standard) for equipment manufacturers, SEMI F47, specifies voltage sag immunity (resistance to momentary voltage drops). Therefore, UPS is not provided by the semiconductor factory, but is often installed by the semiconductor manufacturing equipment manufacturer during manufacturing.

The appropriate size of UPS must be selected depending on the type and scale of the semiconductor manufacturing equipment, but when backing up only the control unit, 1kVA to 3kVA, or at most 5kVA, is often sufficient. On the other hand, when backing up the entire semiconductor manufacturing equipment, a large-capacity UPS of 100kVA or more is required.

A backup time of 1 to 5 minutes is often selected.

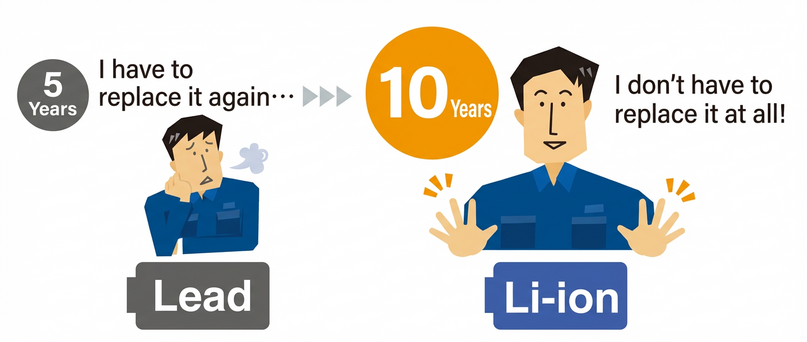

Because the semiconductor manufacturing process is very precise and the products are expensive, stopping semiconductor manufacturing equipment for maintenance requires a lot of effort. The same is true when maintaining the UPS built into semiconductor manufacturing equipment. In the case of a lead-acid battery UPS, the battery life is said to be 2 to 5 years, while the life of a lithium-ion battery is approximately 10 years *2. Considering this, the value of the equipment can be increased by installing a lithium-ion battery UPS with a long battery life.

We also recommend this article: A thorough comparison of UPS lithium-ion batteries and lead-acid batteries!

*2 For SANUPS A11K series.

Semiconductor manufacturing equipment is often used at overseas production bases. In particular, UPS that have acquired UL certification and CE marking are highly valued because they can be exported to the United States, the EU, and other countries.

We also recommend this article: Explaining precautions and safety standards when using UPS overseas!

The control units of semiconductor manufacturing equipment are backed up by individual UPS units to deal with power supply problems. However, power outage countermeasures for larger areas, such as the entire production line, the entire air conditioning equipment, or the entire floor, are also essential in semiconductor factories.

For example, let's say a voltage drop of less than one second occurs due to lightning. Although the control units of each piece of semiconductor manufacturing equipment continue to operate normally thanks to the UPS, the power units of the equipment stop, making it impossible to continue production. Since it takes a considerable amount of time to restart the semiconductor manufacturing equipment, this can result in extremely costly losses in the case of a semiconductor factory.

A large UPS is required to back up an entire line or floor. In large factories, it is not uncommon to install 10 or more 200-300kVA UPS units. Although this represents a large capital investment, in factories that manufacture expensive products such as semiconductors, taking measures against power supply problems can prevent damage that could amount to hundreds of millions of yen due to power outages.

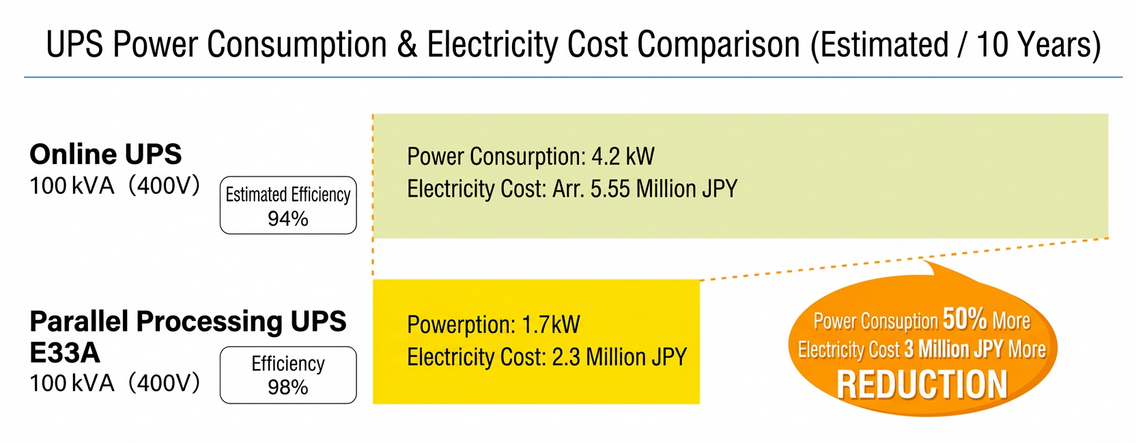

UPS that back up an entire line or floor are very large and use a lot of power. Therefore, choosing a power-efficient, energy-saving UPS can help you save a lot of money on your electricity bill.

In our case, a UPS with Parallel Processing has good power conversion efficiency and helps save energy.

For example, compared to the following UPS, a UPS with Parallel Processing can save more than 3 million yen in electricity bills over 10 years.*3 In addition to the recent surge in electricity prices, the emissions trading system scheduled to begin in 2026 is also attracting attention, so the need for energy-saving UPS may become even greater in the future.

*3 Calculated at 15 yen (tax included) per kWh (estimated value as of April 2023)

The unit price for extra-high voltage varies depending on the contract, so please check the contract details.

An instrumentation system is a device that collects and monitors information from temperature sensors, pressure sensors, etc. It includes functions that measure temperature, pressure, flow rate, etc. using measuring instruments and avoid danger based on the data or automatically control equipment.

Large factories such as semiconductor factories are equipped with a large number of instrumentation devices because even a short stoppage of production equipment can have a significant impact on productivity and cause huge losses.

The power supply for instrumentation systems is often a single-phase 100V system. On the other hand, the power supply for the entire floor or line is often a three-phase 200V/400V system. In other words, a backup for the entire floor or line cannot back up the instrumentation system, and separate measures must be taken to deal with power supply problems.

Furthermore, the shutdown of the instrumentation system due to power outages or other power problems can destabilize the production process and reduce product quality. In the case of semiconductors, which are expensive products, this can have a huge impact and can cause huge losses, so measures must be taken.

The appropriate size UPS must be selected depending on the type and scale of the instrumentation system, but in most cases 1kVA to 3kVA, or at most 5kVA, will be sufficient.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

Ease of maintenance is very important for UPS that backs up instrumentation systems. In semiconductor factories, which have a vast area, a large number of measurement and control devices are installed for each pipe, for example, at specific distances (50 m), etc. And the number of UPS units can reach several thousand in large factories.

In many factories, UPS maintenance is managed using spreadsheet software, and maintenance such as battery replacement requires a great deal of effort. In the case of a lead-acid battery UPS, the battery life is said to be 2 to 5 years, while the life of a lithium-ion battery is approximately 10 years *2. Since 10 years is equivalent to the expected lifespan of a UPS device *4, it is possible to reach the time to replace the UPS without ever having to replace the battery, significantly reducing the amount of maintenance work required.

We also recommend this article: A thorough comparison of UPS lithium-ion batteries and lead-acid batteries!

In addition, UPS for measurement and control equipment requires high reliability and the ability to supply power without momentary interruption.

*2 When the ambient temperature is 25°C.

*4 For SANUPS A11K series.

Supervisor: Toshiyuki Nishizawa, Senior Sales Engineer, Sales Department, SANYO DENKI CO., LTD.

release date: