-

- Free Word Search

Production activities in pharmaceutical factories are carried out in extremely delicate environments that require strict quality control. In such an environment, a stable supply of power using Uninterruptible Power Supplies (UPS) plays a vital role in maintaining strict quality and productivity.

This article focuses on clean rooms, analytical equipment, and pharmaceutical refrigerators as typical pieces of equipment that require backup in pharmaceutical factories, and provides a detailed explanation of the UPS suitable for each and the performance and functions required.

*If used in medical equipment or other devices that directly affect human life, special consideration is required for operation, maintenance, and management. Please consult with us.

Pharmaceutical factory production activities are carried out in biological clean rooms, which are clean rooms that remove not only dust but also microorganisms and bacteria, and are necessary to prevent bacterial contamination in pharmaceutical factories, operating rooms, laboratories, etc., to prevent putrefactive bacteria in food factories, and to prevent cross-contamination in animal breeding facilities.

It is a special clean environment designed to minimize airborne particulate (dust) and microbial contamination, and environmental conditions such as temperature, humidity, and pressure are strictly monitored and controlled.

Since the presence of people would mean that a sterile environment cannot be maintained, the production process itself is carried out in an unmanned, automated environment, and there are cases where many manufacturing devices are located inside clean rooms.

In cleanrooms, environmental conditions such as temperature and humidity are strictly monitored and controlled while maintaining a sterile environment. In the event of a power outage or other power trouble, the important environmental control systems in the cleanroom will stop working, causing changes in the environment. In addition, the operation of many automated manufacturing devices will be affected, resulting in a significant loss of product quality.

This carries the risk of causing significant losses in both time and money, including the disposal of not only work-in-progress but also new drugs currently under research and development, or even the interruption of research altogether.

The appropriate size UPS must be selected depending on the size of the cleanroom, but since it will provide full backup, a large UPS of over 100kVA will often be required.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

It is important for clean rooms to have an uninterrupted power supply in the event of a power outage. For example, if the power supply is cut off during a power outage and the sterility cannot be maintained, there is a risk that not only work in progress but also new drugs under research and development will have to be discarded, or the research itself will be halted, resulting in huge losses in both time and cost. We recommend selecting a UPS that can supply power uninterrupted, such as Double Conversion Online or Parallel Processing.

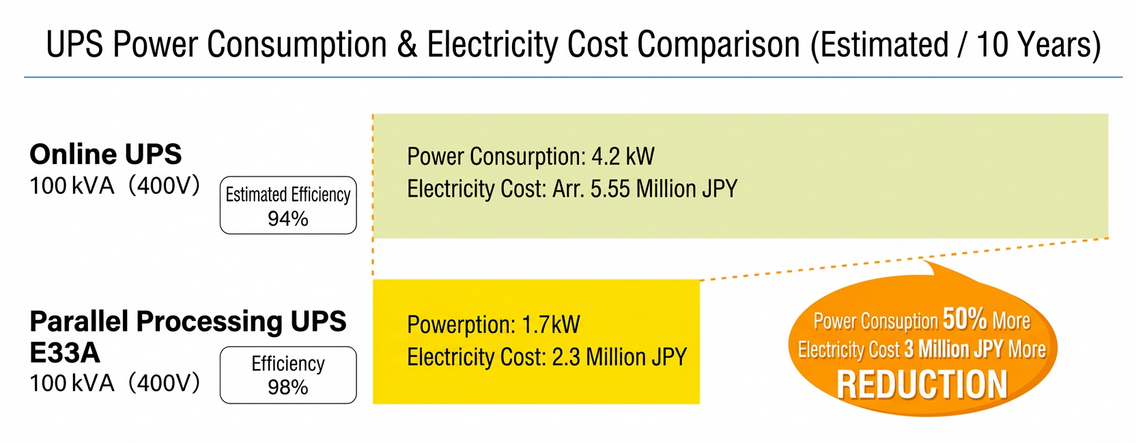

The larger the capacity of a UPS, the more power it consumes, so a UPS with Parallel Processing has good conversion efficiency and contributes to energy savings.

For example, compared to the following UPS, a UPS with Parallel Processing can save more than 3 million yen in electricity bills over 10 years.*3 In addition to the recent surge in electricity prices, the emissions trading system scheduled to begin in 2026 is also attracting attention, so the need for energy-saving UPS may become even greater in the future.

*3 Calculated at 15 yen (tax included) per kWh (estimated value as of April 2023)

*The unit price for extra-high voltage varies depending on the contract, so please check the contract details.

Isolators are extremely important equipment used to maintain a sterile environment in pharmaceutical factories. An isolator is a sealed device that plays a role in maintaining a sterile state by isolating the inside from the outside environment. This prevents products from being exposed to external contaminants (bacteria, viruses, particles, etc.) during processes such as pharmaceutical manufacturing, compounding, and packaging.

Additionally, the environment within the isolator is maintained at strictly controlled temperature, humidity and pressure to ensure a sterile environment.

If a power outage or voltage fluctuation occurs, the isolator may stop functioning and it may become impossible to maintain a sterile environment (or to prove that a sterile state existed), which may lead to serious problems such as waste of work-in-progress or production line shutdowns.

To avoid these risks, it is necessary to use Uninterruptible Power Supplies (UPS) to quickly provide backup power in the event of a power problem.

The appropriate size of UPS must be selected depending on the type and size of the isolator. In terms of capacity, large isolators used in pharmaceutical factory production facilities require a UPS with a capacity of several tens of kVA to 100 kVA or more.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

It is important for an isolator to supply power without momentary interruption during a power outage. For example, if the power supply is cut off during a power outage and the sterility cannot be maintained (or if it becomes impossible to prove that the sterility was there), there is a risk that work in progress will have to be discarded or the production line will have to be stopped, resulting in huge losses in both time and cost. We recommend selecting a UPS that can supply power without momentary interruption, such as Double Conversion Online or Parallel Processing.

In the case of large isolators, a UPS with a large capacity will consume more power, so a UPS with Parallel Processing has good conversion efficiency and contributes to energy savings.

In one case, a UPS using Parallel Processing was able to save more than 3 million yen in electricity bills over a 10-year period.

In pharmaceutical factories, research and development of new drugs is carried out on a daily basis. Analytical instruments are high-precision devices used to perform various tests such as component analysis of products, purity measurement, and evaluation of material properties. These instruments are used to analyze the properties of substances related to pharmacological action and evaluate their effectiveness and safety.

The precision of analytical equipment is required to be extremely high, as it is directly linked to the outcome of R&D and ensuring product quality. Analytical equipment is used in pharmaceutical factories for a wide range of purposes, not just to check product quality, but also to optimize manufacturing processes, research and development of new drugs, and provide materials for approval applications to regulatory authorities.

All of these activities are based on data obtained from highly precise analytical equipment. Therefore, if a power problem causes the power supply to the analytical equipment to be cut off, it can cause significant damage to research and development and production activities, including the loss of important data, the need to repeat analyses, and schedule delays. In order to avoid such risks, a UPS is extremely important.

The appropriate size UPS must be selected depending on the type and scale of the analytical equipment, but in most cases 1kVA to 3kVA, or at most 5kVA, will be sufficient.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

Analytical equipment stores extremely important data that supports the evaluation and safety of drugs. Since the loss of this data can lead to major damage, analytical equipment is required to have Double Conversion Online or Parallel Processing.

A pharmaceutical refrigerator is a piece of equipment used to store pharmaceuticals within a specific temperature range. Improper temperature control can lead to deterioration of pharmaceuticals, so this equipment is essential for maintaining the stability and efficacy of products.

If a power problem causes the power supply to the pharmaceutical refrigerator to be cut off, the quality of the pharmaceuticals cannot be maintained. This can cause significant damage to R&D and production activities, such as the abandonment of new drugs in the research and development process, and schedule delays. UPS is extremely important in order to avoid such risks.

The appropriate size UPS must be selected depending on the type and size of the pharmaceutical refrigerator, but in most cases a 3kVA to 5kVA UPS will be sufficient.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

Ease of maintenance is very important for a UPS that backs up a pharmaceutical cooler. Because a pharmaceutical cooler must be in operation at all times, the UPS that protects it must not cut off the power supply during maintenance. If the UPS has a built-in maintenance bypass circuit, maintenance work can be done while continuing to supply power.

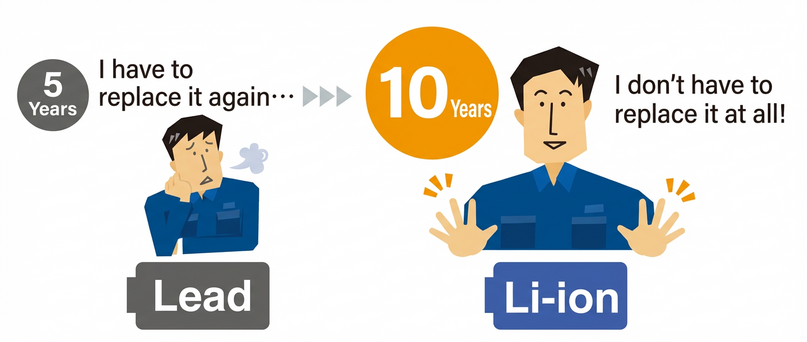

In addition, a lithium-ion battery UPS with a battery life of 10 years * requires less maintenance than a lead-acid battery with a battery life of 2 to 5 years. A lithium-ion battery UPS also has the advantage of being space-saving, allowing you to make effective use of limited space. In addition, storing vaccines and other items requires a large-capacity battery to maintain ultra-low temperatures for several hours, but a lithium-ion battery can be made relatively small.

We also recommend this article: A thorough comparison of UPS lithium-ion batteries and lead-acid batteries!

Supervisor: Toshiyuki Nishizawa, Senior Sales Engineer, Sales Department, SANYO DENKI CO., LTD.

/ Release date: