-

- Free Word Search

Steelworks are constantly operating in harsh, high-temperature environments, with many pieces of equipment and systems in constant motion. Steelworks are large and fraught with the risk of serious accidents, so a stable supply of power provided by Uninterruptible Power Supplies (UPS) plays a vital role in maintaining productivity and safety.

This article focuses on instrumentation systems, central monitoring systems, and process computers as typical equipment to be backed up in steelworks, and provides a detailed explanation of the UPS suitable for each and the performance and functions required.

An instrumentation system is a device that collects and monitors information from temperature sensors, pressure sensors, etc. It includes functions that measure temperature, pressure, flow rate, etc. using measuring instruments and avoid danger based on the data or automatically control equipment.

In factories such as steelworks that operate in harsh environments with constant high temperatures, even a short stoppage of production equipment can have a significant impact on productivity and safety, so a large number of instrumentation devices are installed for each pipe, at specific distances, etc.

The shutdown of an instrumentation system due to a power outage or other power supply problem can destabilize the production process, reduce product quality, and even pose a risk of serious impacts on safety. For example, if an instrumentation system for a temperature sensor in a melting process stops working properly, there is a risk of an explosion or factory fire causing serious damage to the surrounding area.

To ensure constant stable control in an instrumentation system, a UPS backup is essential.

The appropriate size UPS must be selected depending on the type and scale of the instrumentation system, but in most cases 1kVA to 3kVA, or at most 5kVA, will be sufficient.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

Ease of maintenance is very important for UPS that backs up instrumentation systems. Steelworks operate in a vast, high-temperature, harsh environment, and a large number of measurement and control devices are installed on each pipe, at specific distances, etc. Large factories can have several thousand UPS units.

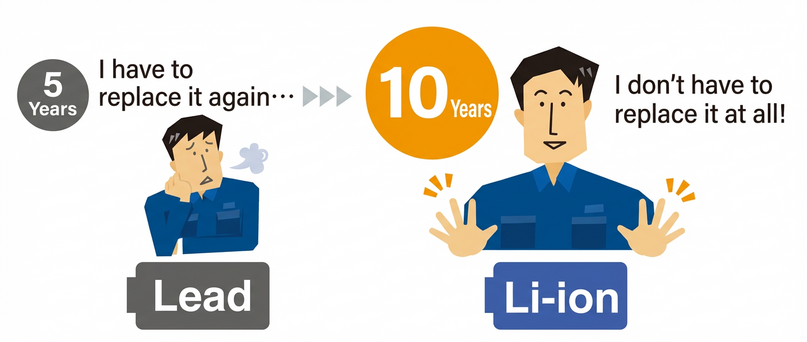

In many factories, UPS maintenance is managed using spreadsheet software, and maintenance such as battery replacement requires a great deal of effort. In the case of a lead-acid battery UPS, the battery life is said to be 2 to 5 years, while the life of a lithium-ion battery is approximately 10 years *1. Since 10 years is equivalent to the expected lifespan of a UPS device *2, it is possible to reach the time to replace the UPS without ever having to replace the battery, significantly reducing the amount of maintenance work required.

We also recommend this article: A thorough comparison of UPS lithium-ion batteries and lead-acid batteries!

In addition, UPS for measurement and control equipment requires high reliability and the ability to supply power without momentary interruption.

*1 When the ambient temperature is 25°C.

*2 For SANUPS A11K series.

This equipment bundles together various equipment in a factory, including measurement and control devices, to monitor and control the equipment. All equipment in the factory is monitored in a single monitoring room.

Steelworks require constant monitoring and control due to the nature of the plant, where accidents can lead to enormous damage. The installation of UPS is important to ensure that monitoring and control are not interrupted by power outages or other power problems.

The appropriate size UPS must be selected depending on the scale of the central monitoring system, but in most cases it is between 20kVA and 50kVA.

When used in conjunction with an emergency generator, the backup time is about 5 minutes to make up for the 1 minute it takes for the generator to start up. When not used in conjunction with a generator, a backup of several tens of minutes to several hours is required until power is restored in the event of a power outage or other power outage.

It is important for a central monitoring system to supply power without interruption during a power outage. For example, if the power supply is cut off during a power outage and the central monitoring system stops, there will be a period of time when the equipment in the factory cannot be monitored. If an accident occurs during that time, there is a risk that it could lead to serious damage such as an explosion or factory fire, so we recommend selecting a UPS that can supply power without interruption, such as Double Conversion Online or Parallel Processing.

Furthermore, if you use a parallel redundant type UPS, you can rest assured that even if one UPS fails, power can continue to be supplied from the other UPS.

The larger the capacity of a UPS, the more power it consumes, so a UPS with Parallel Processing has good conversion efficiency and contributes to energy savings.

We also recommend this article: Reduce your electricity bill by more than 3 million yen in 10 years with more than 50% power consumption!?

This system comprehensively manages and controls the production process, including production line planning, production, and output. It is located between the upper-level vidicon (business computer) that handles production planning, etc., and the lower-level PLC/DCS. It collects and analyzes process data in real time, and outputs commands to optimize process performance.

When a process computer that automates processes in a steelworks stops, it is not as simple as just restarting it immediately. It requires careful checking to determine the cause of the stoppage and whether any abnormalities remain before it can be restored, which is a huge effort. There is also a risk that the process computer stopping itself will cause an accident.

For this reason, process computers are factory equipment that cannot be allowed to stop, and a UPS is extremely important in preventing power supply problems.

You need to select an appropriate size UPS depending on the type and size of your computer, but in most cases a 1kVA to 5kVA UPS will be sufficient.

The process computer is a piece of factory equipment that cannot be allowed to stop. In the event of a power outage or other emergency, if the UPS that supplies power to the process computer breaks down, it will be a disaster. With a parallel redundant type UPS, you can rest assured that even if a UPS breaks down, power can continue to be supplied from another UPS.

In addition, the UPS that backs up the process computer must be highly reliable and capable of supplying power without interruption.

Supervisor: Toshiyuki Nishizawa, Senior Sales Engineer, Sales Department, SANYO DENKI CO., LTD.

release date: